This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

Unlocking Efficiency: Your Beginner’s Guide to Selecting the Best Grain Handling Equipment for Your Farm

In the ever-evolving world of agriculture, the intersection of technology and tradition presents a myriad of opportunities for farmers looking to streamline their operations. Whether you’re cultivating a few acres or managing a sprawling expanse, one vital aspect remains true: effective grain handling is essential for maximizing productivity and minimizing losses. For those new to the field or venturing into grain management, selecting the right equipment can be a daunting task amidst the vast array of options available. Fear not—this beginner’s guide is designed to demystify the process, providing you with the insights and considerations necessary to choose the best grain handling equipment tailored to your unique farm needs. With an informed approach, you’ll be well on your way to enhancing efficiency, preserving crop quality, and ultimately, ensuring a bountiful harvest. Let’s embark on this journey together, unlocking the potential of your agricultural endeavors, one piece of equipment at a time.

Understanding Your Grain Handling Needs

When choosing the right grain handling equipment, it’s essential to assess your specific operational needs. Factors such as the type and quantity of grain, the layout of your farm, and your budget play a crucial role in this decision-making process. Consider the following aspects when evaluating your requirements:

- Type of Grain: Different grains require different handling methods, which may affect equipment choice.

- Volume: Estimate how much grain you will store or process. This helps determine the capacity and scale of the equipment you need.

- Space Availability: Analyze your facility’s layout to ensure you can accommodate the necessary machinery without compromising operational efficiency.

- Budget Constraints: Establish a realistic budget that includes not only the initial purchase but ongoing maintenance and operational costs.

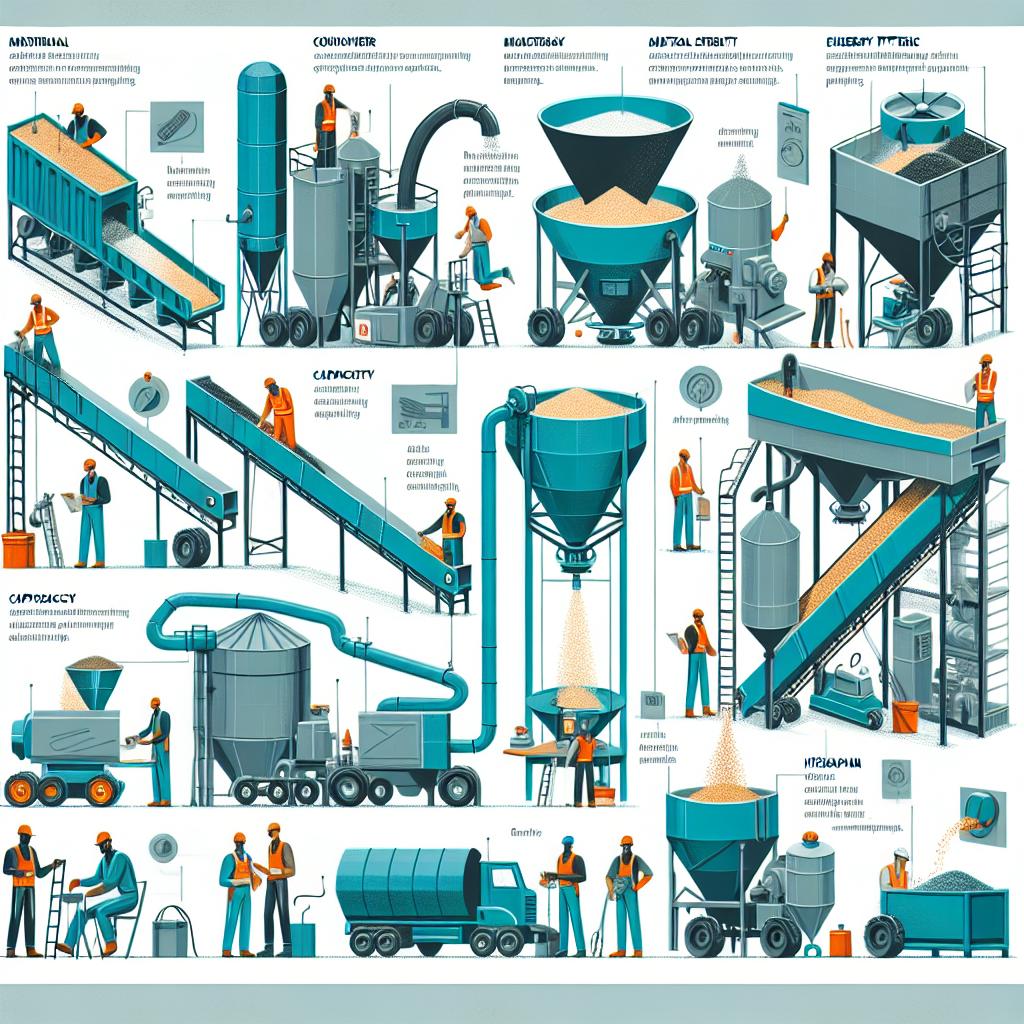

Additionally, there are specific types of equipment to consider, each tailored to various handling tasks. Understanding the core functions of these machines is vital in making a well-informed choice. Below is a simple comparison of some common grain handling equipment:

| Equipment Type | Function | Best For |

|---|---|---|

| Grain Augers | Moving grain from one location to another | Small to medium farms with limited space |

| Grain Elevators | Transporting grain vertically | Larger operations requiring high throughput |

| Grain Bins | Storage of harvested grain | Farms needing long-term grain preservation |

Evaluating Equipment Options for Efficiency and Reliability

When selecting grain handling equipment, consider not only the purchase price but also the long-term efficiency and reliability it brings to your operation. High-efficiency machines can significantly reduce fuel and labor costs, allowing your farm to operate more smoothly over time. Moreover, reliable equipment minimizes downtime, ensuring that you’re always ready to tackle the harvest at peak times. Look for machines with strong warranties and proven resilience in challenging working conditions, as these are indicators of reliability.

To help you make an informed decision, here’s a quick comparison of essential features to look for in grain handling equipment:

| Feature | Importance | Recommended Brands |

|---|---|---|

| Energy Efficiency | Reduces operational costs | Brand A, Brand B |

| Durability | Minimizes repairs and replacement | Brand C, Brand D |

| Ease of Maintenance | Ensures longevity and performance | Brand E, Brand F |

When weighing these features, don’t forget to compare the after-sales service offered by manufacturers. A brand that provides extensive customer support, including training and maintenance programs, often gives you more peace of mind and helps maximize the lifespan of the equipment. Other considerations may include the availability of spare parts and the accessibility of service technicians in your area, which can greatly influence your equipment’s overall uptime and performance.

Key Features to Consider When Choosing Grain Handling Equipment

When selecting grain handling equipment, there are several pivotal elements to assess to ensure the chosen machinery aligns perfectly with your farming needs. Capacity is critical; you must evaluate the amount of grain your farm produces and select equipment that can handle your peak harvest efficiently. Additionally, consider the material types you will be working with, as certain machines are better suited for different grains, whether it’s wheat, corn, or soybeans. It’s equally important to look into the durability of the equipment, as well-built machines can withstand the rigors of grain handling for years, leading to lower long-term costs.

Another vital aspect to examine is the ease of use. Select equipment that offers intuitive controls and minimal maintenance requirements to save time and reduce labor costs. Your space limitations should also dictate choice; check the dimensions and mobility of the equipment, as compact machines may be necessary for smaller farms. Additionally, consider the manufacturer’s support services; reliable post-purchase service and availability of parts can significantly impact operational efficiency. Taking these factors into account will facilitate a more informed decision, leading to better productivity on your farm.

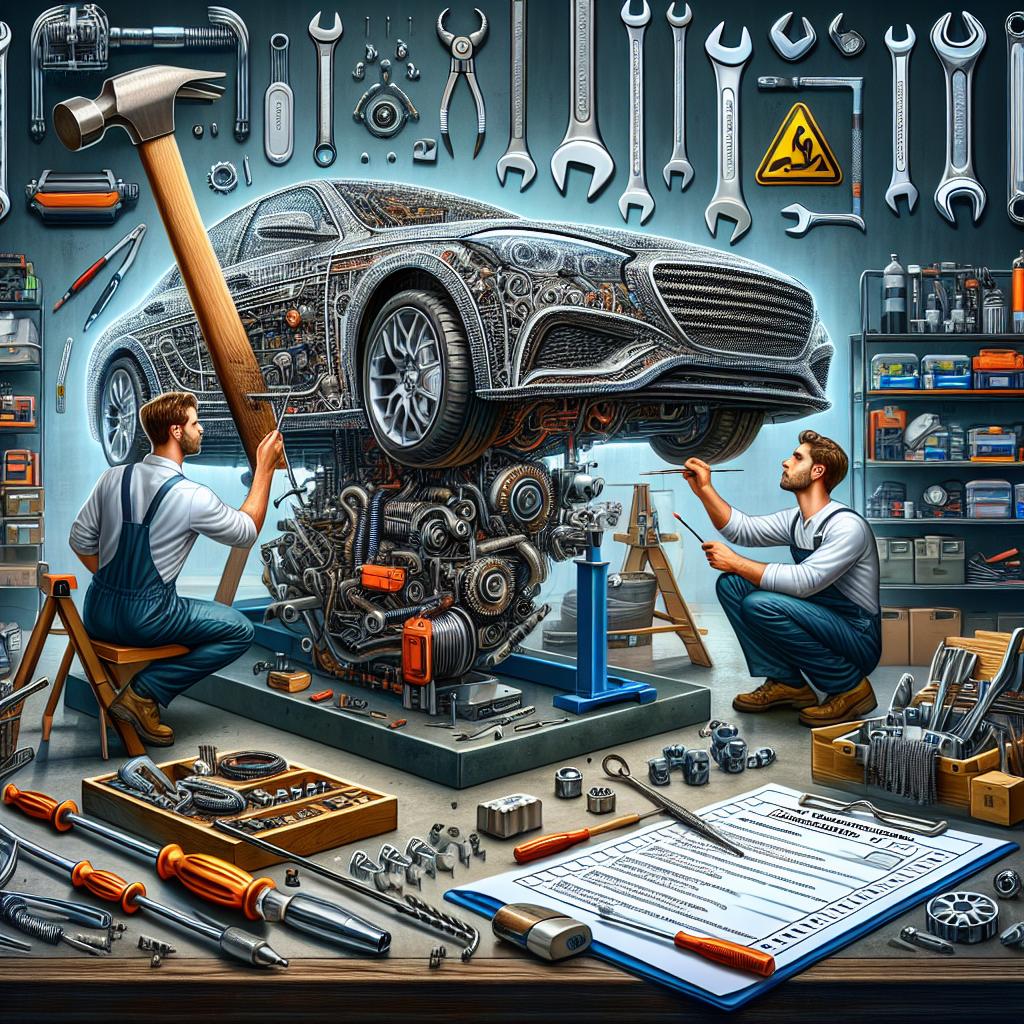

Maintenance and Upkeep: Ensuring Longevity and Performance

To ensure your grain handling equipment remains efficient and reliable over the years, regular maintenance and upkeep are essential. This not only protects your investment but also enhances productivity on your farm. A well-structured maintenance schedule can help in identifying potential problems before they escalate into costly repairs. Key areas to focus on include:

- Regular inspections: Check for wear and tear on belts, bearings, and other moving parts.

- Lubrication: Ensure all moving components are lubricated to reduce friction and wear.

- Cleaning: Keep equipment free of dust, debris, and grain residues that can hinder performance.

Additionally, tracking the performance of your equipment can provide valuable insights into its condition. Keeping a record can help identify patterns, allowing for more informed decisions about repairs or replacements. Consider using a simple table format to log maintenance activities and performance metrics, as shown below:

| Date | Activity | Comments |

|---|---|---|

| 01/15/2023 | Lubrication | Greased all bearings and checked fluid levels. |

| 02/10/2023 | Inspection | Replaced worn belts and tightened loose screws. |

By adhering to a systematic maintenance routine and documenting your efforts, you can enhance the longevity and performance of your grain handling equipment. Remember that a proactive approach will save you time, money, and headaches in the long run.

Q&A

Beginner’s Guide to Selecting the Best Grain Handling Equipment for Your Farm: Q&A

Q1: What is grain handling equipment and why is it essential for my farm?

A1: Grain handling equipment encompasses a range of tools and machinery designed to collect, store, transport, and process grains. Essential for smooth operations, it helps reduce labor costs, minimizes grain loss, and maintains the quality of your harvest. Whether you’re managing a small plot or a vast expanse of farmland, the right equipment can significantly enhance your efficiency and productivity.

Q2: How do I determine the right size of grain handling equipment for my needs?

A2: The right size depends on several factors, including the size of your farm, the volume of grain produced, and the type of grain you are handling. Consider your average yield, as well as your future growth projections. It’s advisable to consult with equipment dealers who can help you assess your requirements and suggest suitable options based on your specific situation.

Q3: What types of grain handling equipment should I consider?

A3: Key types of grain handling equipment include grain bins, augers, conveyors, dryers, and grain vacuums. Each serves a distinct purpose, from storing and drying to transporting grain efficiently. Start by identifying the specific processes you need – such as storage or transport – and then explore the equipment that meets those needs effectively.

Q4: Are there specific features I should look for when selecting equipment?

A4: Yes! Look for features that enhance efficiency, safety, and ease of use. Consider equipment with adjustable speeds, easy maintenance access, and safety guards. Also, durability and weather resistance are crucial for longevity. Many models also come with automation features, which can save time and labor, so be on the lookout for the latest technology that fits your needs.

Q5: What should my budget look like when investing in grain handling equipment?

A5: Your budget will vary based on your farm’s scale and the chosen equipment’s capacity and sophistication. Establish a clear budget before shopping to avoid overspending. Always factor in maintenance and operational costs, and consider financing options or grants that may be available to help ease the financial burden of purchasing high-quality equipment.

Q6: How can I ensure the equipment I choose is reliable?

A6: Start by researching reputable manufacturers and brands known for quality and durability. Reading reviews from other farmers and consulting with local agricultural extension services can also provide insight. Additionally, consider asking for demonstrations of the equipment before purchasing, and investigate warranty options to safeguard your investment.

Q7: What should I do if I’m overwhelmed by the options available?

A7: It’s perfectly normal to feel overwhelmed! Begin by outlining your specific needs and constraints. Reach out to local agricultural extension offices, farming cooperatives, or experienced peers for guidance. Sometimes, a consultation with an equipment dealer can also clarify options, as they can tailor recommendations based on your farm’s unique characteristics.

Q8: Are there any advances in technology that I should be aware of?

A8:Absolutely! Recent advancements include automated systems for grain handling that optimize freight and storage management, precision sensors that monitor grain quality, and integrated software solutions that streamline operations. Investing in such technology can lead to better decision-making and enhance overall efficiency on your farm.

Q9: Can I combine different types of equipment for a more efficient operation?

A9: Yes, combining different types of equipment can offer a customized solution tailored to your farm’s specific needs. For example, integrating grain vacuums with augers can enhance the speed and ease of transporting grains. Evaluate how various equipment can work in harmony to streamline processes, reduce manual labor, and improve yield efficiency.

Q10: Any final tips for beginners selecting grain handling equipment?

A10: Take your time. Research thoroughly, consult with experts, and seek input from fellow farmers. Visit trade shows to see equipment in action and consider your long-term needs while making a decision. Remember, the right equipment is an investment in your farm’s future — one that should suit your operational needs and trajectory.

As you embark on this journey of selecting the best grain handling equipment, remember that thoughtful consideration and research are your best allies. Happy farming!

Wrapping Up

As we come to the end of this beginner’s guide, it’s clear that navigating the world of grain handling equipment can feel daunting at first glance. However, armed with the right knowledge and insights, you can confidently make choices that will enhance your farm’s productivity and efficiency. Remember to take into account your specific needs, budget, and the unique characteristics of your operation.

Choosing the proper grain handling equipment is not just a task; it’s an investment in the future of your farming endeavors. By considering factors such as capacity, durability, and your long-term goals, you can ensure that the equipment you select supports your journey towards success. So take a deep breath, weigh your options, and know that each decision brings you one step closer to mastering the art of grain handling.

As you embark on this journey, keep an open mind and don’t hesitate to seek advice from fellow farmers and equipment specialists. With the right tools at your disposal, you’ll not only streamline your processes but also pave the way for fruitful harvests to come. Happy farming!

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.