This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

Maintaining your center pivot irrigation system is vital for ensuring its optimal performance and longevity. This article provides essential maintenance tips that will help you keep your system running smoothly. From regular inspections and lubrication to checking for leaks and monitoring water pressure, these simple yet crucial steps will ensure that your center pivot irrigation system remains in top condition, providing efficient and effective irrigation for your crops. So, read on to discover the key maintenance tips that will help you get the most out of your system and keep it operating at its best.

Inspecting the Pivot Point

When it comes to maintaining your center pivot irrigation system, regularly inspecting the pivot point is crucial. This is where the entire system rotates, so any issues here can have a significant impact on the system’s performance. Start by checking for loose bolts and nuts. Over time, these can become loose due to the continuous movement of the system. Tighten any loose bolts or nuts to ensure the pivot point remains stable.

Next, inspect the pivot point alignment. A misaligned pivot point can result in uneven water distribution and inefficient watering. Check that all the towers are properly aligned and parallel to each other. If you notice any misalignment, adjust the towers accordingly to ensure optimal performance.

Lastly, check for excessive wear and tear. Look for signs of damage or deterioration in the pivot point components, such as worn-out bearings or cracked welds. Replace any worn or damaged parts to prevent further issues and ensure the longevity of your irrigation system.

Examining the Tower Structure

The tower structure of your center pivot irrigation system is responsible for supporting and guiding the movement of the system. It’s important to regularly examine this structure to identify any potential issues that may affect its functionality.

First, check the tower alignment. Make sure that each tower is upright and aligned with the others. Any misalignment can lead to unequal water coverage and ineffective irrigation. Adjust the towers if necessary to ensure they are all properly aligned.

Next, inspect the tower structure for corrosion or rust. Exposure to moisture and environmental elements can cause these issues over time. Rust or corrosion weakens the structure and compromises its integrity. If you notice any signs of rust or corrosion, treat the affected areas or replace the damaged parts to prevent further deterioration.

Additionally, check for loose or broken parts in the tower structure. Shaking or movement can sometimes cause bolts, nuts, or other components to become loose or even break. Tighten any loose parts and replace any broken ones for a sturdy and reliable tower structure.

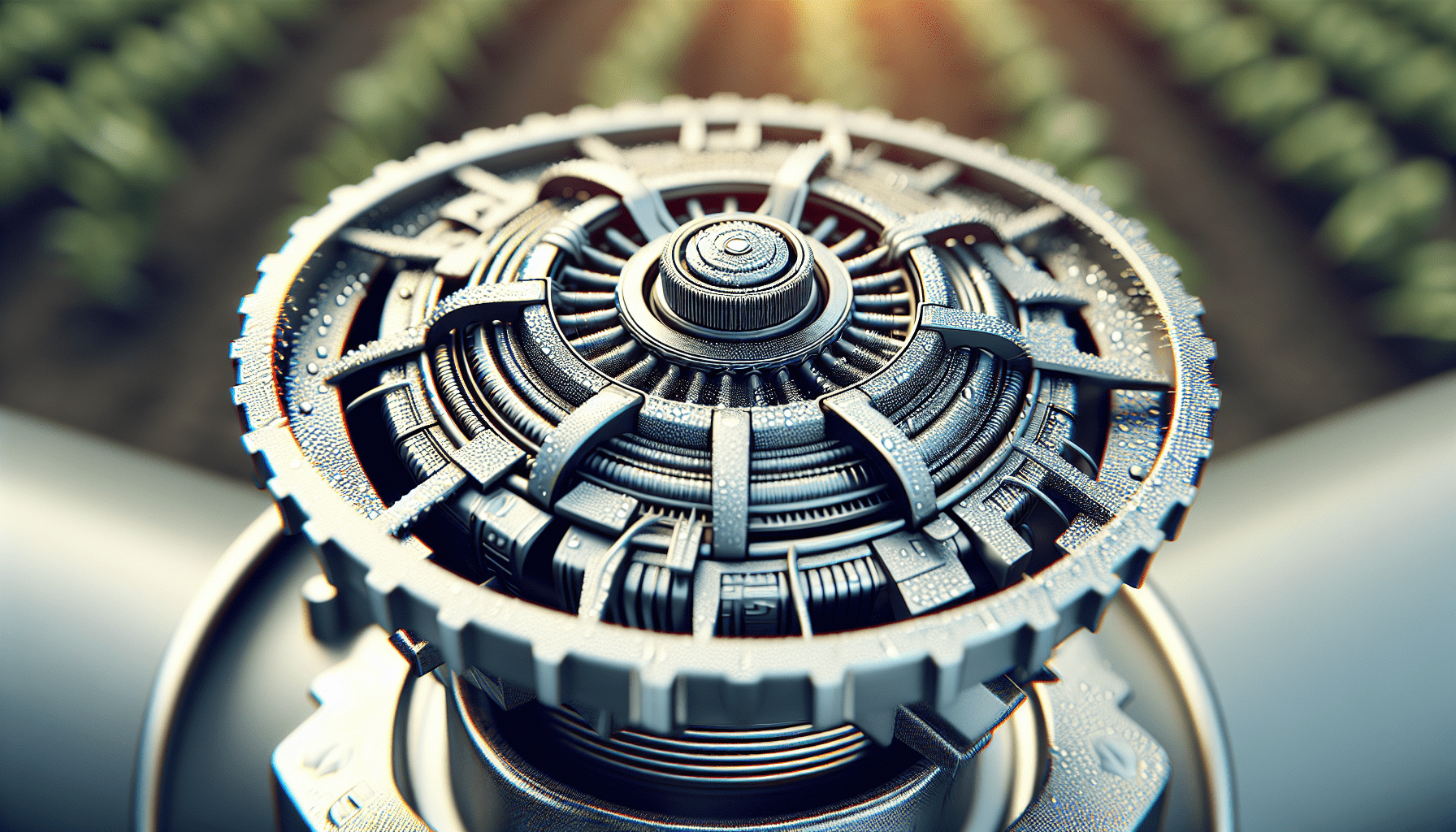

Checking the Sprinkler Package

The sprinkler package is the heart of your center pivot irrigation system, as it delivers water to the crops. Regular inspection of the sprinkler package is essential to ensure optimal water distribution and overall system performance.

Start by inspecting the sprinkler nozzles. Check for any clogs, dirt, or debris that may affect the water flow. Clean or replace any clogged nozzles to maintain consistent and uniform water distribution.

Next, check the pressure regulators. These components regulate the water pressure throughout the system. Make sure they are functioning properly and not leaking. Test the pressure ratings to ensure they meet the required specifications. If you notice any issues or inconsistencies, repair or replace the pressure regulators accordingly.

Inspecting the Pivot Alignment

Proper pivot alignment is crucial for the efficient operation of your center pivot irrigation system. By inspecting the alignment of each tower and the end tower, you can ensure uniform water coverage and prevent overwatering or under-irrigation.

Start by checking the alignment of each tower. They should be parallel to each other and evenly spaced. If there are any deviations or misalignments, adjust the towers accordingly to maintain a straight and balanced pivot line.

Next, inspect the alignment of the end tower. This tower is responsible for initiating the system’s movement and needs to be properly aligned to ensure smooth operation. Make sure it is straight and aligned with the rest of the system. If there are any alignment issues, adjust the end tower to prevent stress on the system and maximize its efficiency.

Examining the Electrical System

The electrical system of your center pivot irrigation system plays a crucial role in controlling its movement and overall functionality. Regularly examining the electrical components is essential to ensure reliable operation and prevent any potential hazards.

Start by checking the wiring connections. Make sure all the connections are secure and free from any damage or corrosion. Loose or damaged connections can lead to electrical malfunctions or system failures. Tighten or repair any faulty connections to ensure proper electrical flow.

Next, test the safety switches and relays. These components are designed to protect the system from electrical issues and prevent damage. Verify that they are functioning correctly and activating when needed. If any safety switches or relays are not working properly, replace them to maintain a safe and reliable system.

Lastly, inspect the control panel for any damage. The control panel houses various electrical components and controls the operation of the system. Look for signs of wear, damage, or water infiltration. If any issues are detected, repair or replace the control panel to ensure the proper functioning of your center pivot irrigation system.

Maintaining the Drivetrain

The drivetrain is responsible for transferring power from the motor to the wheels, enabling the movement of the center pivot irrigation system. Proper maintenance of the drivetrain is essential to ensure smooth and efficient operation.

Start by checking the gearbox oil levels. Insufficient oil levels can lead to increased friction, heat, and premature wear of the gearbox components. Make sure the oil levels are within the recommended range. If needed, top up or replace the gearbox oil to ensure optimal lubrication and performance.

Next, inspect the drive chains for any signs of wear or damage. Look for stretched links, excessive rust, or broken sections. Worn or damaged drive chains can affect the movement of the system and compromise its efficiency. Replace any damaged chains to maintain a reliable drivetrain.

Lastly, lubricate the drivetrain components regularly. Apply a suitable lubricant to the gears, sprockets, and bearings to reduce friction and prevent premature wear. Proper lubrication ensures smooth operation and extends the lifespan of the drivetrain.

Cleaning and Adjusting the Sprinkler Package

Regular cleaning and adjustment of the sprinkler package are essential to ensure optimal water distribution and efficient irrigation. Here are some steps to follow:

Start by cleaning debris from the sprinkler nozzles. Debris such as dirt, leaves, or insects can clog the nozzles and disrupt the water flow. Use a soft brush or compressed air to remove any debris and ensure unobstructed water distribution.

Next, adjust the sprinkler operating pressure. The pressure should be set according to the specific irrigation requirements of your crops. Consult the system’s manual or a professional for guidance on the appropriate operating pressure. Adjust the pressure regulators accordingly to achieve the desired water application.

Lastly, check the uniformity of water application. Walk the length of the system and observe the water distribution patterns. Make sure there are no dry or excessively wet areas. Adjust the sprinkler package if needed to ensure uniform coverage and efficient water usage.

Inspecting the Pressure Regulators

Pressure regulators are vital components of your center pivot irrigation system, as they maintain a consistent water pressure throughout the system. Regular inspection of the pressure regulators is crucial to ensure optimal performance and prevent any potential issues.

Start by checking for leaks or damage in the pressure regulators. Inspect the components for any signs of water leakage or physical damage. Leaks can lead to water loss and inefficient irrigation. Replace any damaged or faulty regulators to ensure proper water pressure regulation.

Next, clean or replace any clogged pressure regulators. Over time, mineral deposits or debris can accumulate, leading to blockages and decreased performance. Remove any clogs using a suitable cleaning solution or replace the regulators if they are severely clogged or damaged.

Lastly, test the pressure ratings of the regulators. Make sure the actual pressure matches the specified pressure range. Deviations from the recommended pressure can affect the system’s performance and potentially damage crops. If there are any inconsistencies, adjust or replace the pressure regulators accordingly.

Maintaining the Water Supply

The water supply is a crucial element of your center pivot irrigation system. Proper maintenance of the water supply components ensures a reliable and efficient water source for your crops.

Start by inspecting the valves and filters. Check for any leaks, damage, or blockages. Leaky valves can result in water loss and inefficient irrigation, while clogged filters restrict water flow. Repair or replace any faulty valves or filters to ensure a consistent water supply.

Next, flush the irrigation system periodically to remove sediment or debris that may accumulate over time. Flushing helps maintain the flow rate and prevent blockages in the system. Follow the manufacturer’s instructions or consult a professional for guidance on the proper flushing procedure.

Lastly, check the water pressure and flow rate. Make sure they meet the recommended levels for your irrigation needs. Inadequate water pressure or flow can negatively impact the system’s performance and crop health. If necessary, consult with a professional to optimize the water supply for your specific requirements.

Winterizing the System

Proper winterization of your center pivot irrigation system is essential to protect its components from freezing temperatures and potential damage. Here are some steps to follow:

Start by draining water from the pipes and sprinklers to prevent freezing. Standing water can expand when frozen, leading to burst pipes or damaged sprinklers. Use appropriate drainage methods to ensure all water is removed from the system.

Next, protect electrical components from freezing temperatures. Insulate any exposed wires or electrical boxes to prevent damage from freezing or moisture. Consider using insulation wraps, heat tapes, or other suitable methods to safeguard the electrical components.

Lastly, before the spring use, inspect the entire system for any signs of damage or wear. Look for any broken parts, leaks, or other potential issues that may have occurred during the winter months. Repair or replace any damaged components to ensure the system’s proper functioning and prevent potential problems during operation.

By following these essential maintenance tips for your center pivot irrigation system, you can ensure its longevity, optimal performance, and efficient watering of your crops. Regular inspections, cleaning, and adjustments go a long way in preventing potential issues and maximizing the system’s effectiveness. Remember to consult the system’s manual or seek professional assistance whenever needed to ensure proper maintenance and care.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.