This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

If you’re in the market for used farm equipment, you may find yourself pondering this question: how can you accurately assess the quality of a second-hand piece of machinery? With so many factors to consider, like wear and tear, maintenance history, and overall functionality, it’s essential to have a clear understanding of what to look for. In this article, we will explore some helpful tips and guidelines to help you confidently evaluate the quality of used farm equipment, ensuring that you make a wise investment for your agricultural needs. So, let’s dive in and discover how to make informed decisions when purchasing pre-owned farm equipment.

1. Visual Inspection

1.1 Exterior Condition

When assessing the quality of a used piece of farm equipment, the first step is to conduct a visual inspection of the exterior. Look for any signs of damage or wear, such as dents, scratches, or rust. Check the paint job and see if there are any areas where the paint is peeling or fading. These could be indicators of how well the equipment has been maintained and cared for.

1.2 Interior Condition

Next, carefully inspect the interior of the equipment. Check the seats, steering wheel, and controls for any signs of excessive wear or damage. Look for any cracks or tears in the upholstery. A clean and well-maintained interior is usually a good indication that the equipment has been taken care of properly.

1.3 Surface Rust

Surface rust is a common issue in used farm equipment, especially in those exposed to harsh weather conditions. Take a close look at the equipment’s exterior and inspect for any signs of rust. Surface rust can be tackled easily with proper maintenance, but severe or structural rust may require costly repairs.

1.4 Damage or Wear

During the visual inspection, be on the lookout for any significant damage or wear. Check for bent or broken parts, loose or missing bolts, and any signs of repairs or modifications. Pay attention to the tires and inspect their condition and tread depth. Any unexpected wear patterns or uneven tread may suggest underlying mechanical problems.

2. Mechanical Inspection

2.1 Engine

The engine is the heart of any farm equipment, and it is essential to thoroughly inspect it. Check for any signs of oil leaks or excessive smoke from the exhaust. Look for oil or coolant contamination and ensure that the engine starts smoothly and idles without any unusual noises or vibrations. It might be beneficial to have a professional mechanic assess the engine’s condition to ensure its reliability.

2.2 Transmission

The transmission is responsible for transferring power from the engine to the equipment’s wheels or other moving parts. Test the various gears to ensure smooth shifting and acceleration. Any grinding or slipping can indicate transmission issues. Additionally, check the transmission fluid level and quality, as dirty or burnt fluid could be a sign of neglect or impending problems.

2.3 Hydraulics

Hydraulic systems are crucial for many farm equipment operations. Inspect the hydraulic components for any leaks, damaged lines, or worn-out seals. Check the responsiveness of the hydraulic controls and ensure that they operate smoothly without any delays or jerking motions. Proper functioning hydraulics are essential for optimal performance and efficiency.

2.4 Electrical System

Modern farm equipment often relies on intricate electrical systems, so it’s important to assess their condition. Test all the equipment’s electrical functions, including lights, indicators, and switches. Look for any signs of exposed or frayed wiring, loose connections, or blown fuses. A well-maintained electrical system is necessary to prevent potential safety hazards and ensure proper functionality.

This image is property of www.devicemagic.com.

3. Maintenance Records

3.1 Service History

One of the most valuable pieces of information when assessing the quality of used farm equipment is its service history. Ask the seller if they have comprehensive records of all maintenance and repairs performed on the equipment. Regular servicing, oil changes, and scheduled maintenance indicate that the equipment has been well cared for. If there are no records available, it may be wise to proceed with caution or seek an independent inspection.

3.2 Regular Maintenance

Find out if the equipment has undergone routine maintenance tasks such as lubrication, filter replacements, and belt inspections. Proper and regular maintenance is crucial to prolonging the life of the equipment and preventing costly breakdowns. By reviewing maintenance records or receipts, you can determine if the equipment has been properly serviced as recommended by the manufacturer.

3.3 Repairs and Replacements

Inquire about any significant repairs or component replacements that have been performed on the equipment. Understanding the repair history can shed light on potential recurring issues or underlying problems. Ensure that all repairs have been carried out by qualified professionals and with genuine parts. It’s also important to know if any major components, such as the engine or transmission, have been rebuilt or replaced entirely.

4. Operating Tests

4.1 Start-up and Idle

Before making a purchase, it’s essential to start up the equipment and observe its behavior during idle. Ensure that it starts easily without any excessive smoke or abnormal noises. Pay attention to how the engine behaves during the warm-up period. Observe for any signs of stalling, rough idling, or irregular RPM fluctuations, as these may indicate potential issues.

4.2 Acceleration and Power

Take the equipment for a test drive or operate it in a controlled environment to assess its acceleration and power. Observe how the equipment responds when you accelerate, focusing on whether it achieves the expected speed and power effortlessly. Any hesitation or lack of power may suggest mechanical problems or insufficient maintenance.

4.3 Steering and Braking

Test the steering system by turning the equipment at low and high speeds. Ensure that the steering is responsive and free of any excessive play or stiffness. Additionally, assess the braking system for quick and effective braking without any unusual noises or vibrations. Any issues with steering or braking can compromise safety and should be thoroughly examined.

4.4 Equipment Functions

Engage and test all the equipment’s functions and attachments to ensure they operate smoothly and as expected. This may include operating the PTO (Power Take-Off), engaging hydraulic functions, or testing specific implements. Pay close attention to any unusual noises, vibrations, or delays in response. A thorough assessment of all equipment functions is critical to verify its overall functionality.

This image is property of www.farm-equipment.com.

5. Fluid Analysis

5.1 Engine Oil

Conducting a fluid analysis, starting with the engine oil, can provide valuable insight into the equipment’s internal condition. Check the engine oil’s color, consistency, and smell. Clean, amber-colored oil is desirable, while dark or milky oil may indicate potential issues with lubrication, coolant leaks, or engine damage.

5.2 Hydraulic Fluid

Next, analyze the hydraulic fluid used in the equipment. Ensure that the fluid level is adequate and that there are no signs of contamination or debris. Milky or frothy hydraulic fluid may suggest water infiltration, while burnt or discolored fluid could indicate severe overheating or component wear.

5.3 Coolant

Inspect the coolant reservoir to verify that the coolant level is within the recommended range. Check the condition of the coolant, ensuring it is clean and free of debris or oil contamination. Discolored or rusty coolant may indicate potential cooling system problems or lack of proper maintenance.

5.4 Fuel

Lastly, evaluate the fuel quality. Check for any signs of water contamination or sediment in the fuel tank or filters. Water or debris in the fuel system can lead to poor engine performance and potential damage. Ensure that the fuel is fresh and free from any contaminants.

6. Check for Leaks

6.1 Oil Leaks

Thoroughly inspect the equipment for any signs of oil leaks, particularly around the engine, transmission, and hydraulic components. Look for drips, oil stains, or wet spots on the ground or under the equipment. Even small leaks can indicate underlying issues, and addressing them promptly can prevent further damage.

6.2 Hydraulic Leaks

Hydraulic leaks can significantly impact the performance and reliability of farm equipment. Check for any visible leaks in the hydraulic lines, fittings, or cylinders. Pay attention to any signs of fluid accumulation or wetness. Hydraulic leaks can lead to reduced hydraulic power, equipment malfunctions, or even safety hazards if not addressed promptly.

6.3 Fuel Leaks

Inspect the fuel system for any signs of fuel leaks. Check the fuel lines, connections, and fuel tank for visible drips, stains, or fuel odors. Fuel leaks can not only impact the efficiency of the equipment but also pose a significant fire hazard. Addressing fuel leaks is crucial to ensure safe operation.

6.4 Coolant Leaks

Lastly, check for any coolant leaks in the equipment. Coolant leaks can lead to overheating, engine damage, or even catastrophic failure. Look for any signs of coolant stains, drips, or a sweet odor. Addressing coolant leaks promptly is essential to prevent potential costly repairs or engine damage.

This image is property of i0.wp.com.

7. Test Drive

7.1 Ease of Starting

During the test drive, pay attention to how easily the equipment starts. A well-maintained and reliable piece of farm equipment should start without hesitation, even in cold conditions. Uneven or prolonged cranking may indicate potential issues with the starting system or battery.

7.2 Engine Performance

Assess the overall performance of the engine during the test drive. Note if there are any unusual noises, vibrations, or excessive exhaust smoke. The engine should run smoothly, provide ample power, and respond well to acceleration and throttle inputs. Any signs of engine misfire or lack of power may indicate underlying mechanical problems.

7.3 Transmission and Gears

Test the various gears and the equipment’s ability to smoothly shift between them. The transmission should engage without any grinding or slipping. Ensure that all gears are functional and that the equipment can efficiently make transitions between them. Any unexpected noises, difficulty shifting, or gear slipping might indicate potential transmission issues.

7.4 Handling and Suspension

Lastly, evaluate the handling and suspension of the equipment during the test drive. Observe how the equipment responds to steering inputs and if it feels stable and well-balanced. Pay attention to any excessive bouncing, shaking, or vibrations, as these may suggest problems with the suspension or other key components.

8. Structural Integrity

8.1 Frame

Inspect the frame of the equipment for any signs of damage, cracks, or welds. A solid and intact frame is essential for the overall structural integrity and safe operation of farm equipment. Any visible damage or repairs should be carefully examined to ensure they were properly addressed.

8.2 Body

Check the body of the equipment for any signs of damage, such as dents, scratches, or rust. Minor cosmetic issues may not impact the performance, but significant body damage or rust can compromise the equipment’s structural integrity and lead to future problems.

8.3 Chassis

The chassis provides the foundation for the equipment’s body and components. Inspect the chassis for any signs of rust, cracks, or fatigue. Pay close attention to critical areas such as the suspension mounting points or stress-prone locations. A structurally sound chassis is essential for ensuring the equipment’s safety and longevity.

8.4 Attachments

If the equipment comes with attachments or implements, assess their condition and functionality. Check for any signs of wear, damage, or distorted components. Ensure that all attachments can be easily and securely connected to the equipment. Properly functioning attachments are crucial for achieving optimal operational efficiency and productivity.

This image is property of www.agriculture.com.

9. Previous Use and History

9.1 Recording Usage

Inquire about how the equipment was used in the past. Understand the type of work it was employed for and if it matches your intended application. Equipment used for heavy-duty tasks or in harsh conditions may have experienced more wear and tear, requiring closer inspection and consideration.

9.2 Tracking Accidents or Damages

Determine if the equipment has been involved in any accidents, collisions, or incidents that may have caused damage. Ask the seller about any repairs that were undertaken as a result. It’s important to be aware of the equipment’s accident history to assess potential long-term effects on performance and structural integrity.

9.3 Previous Owners

Inquire about the number of previous owners the equipment has had. A well-maintained machine with fewer owners often suggests a higher likelihood of proper care and maintenance. If there have been numerous owners, it may be worth investigating further to determine if there have been any recurring issues or inconsistent maintenance practices.

9.4 Warranty Information

Check if the equipment comes with any remaining warranty or extended warranty. The presence of a warranty can provide peace of mind and protection against unexpected repair costs. Make sure to review the warranty terms and conditions to understand what is covered and if it can be transferred to the new owner.

10. Price Evaluation

10.1 Market Value

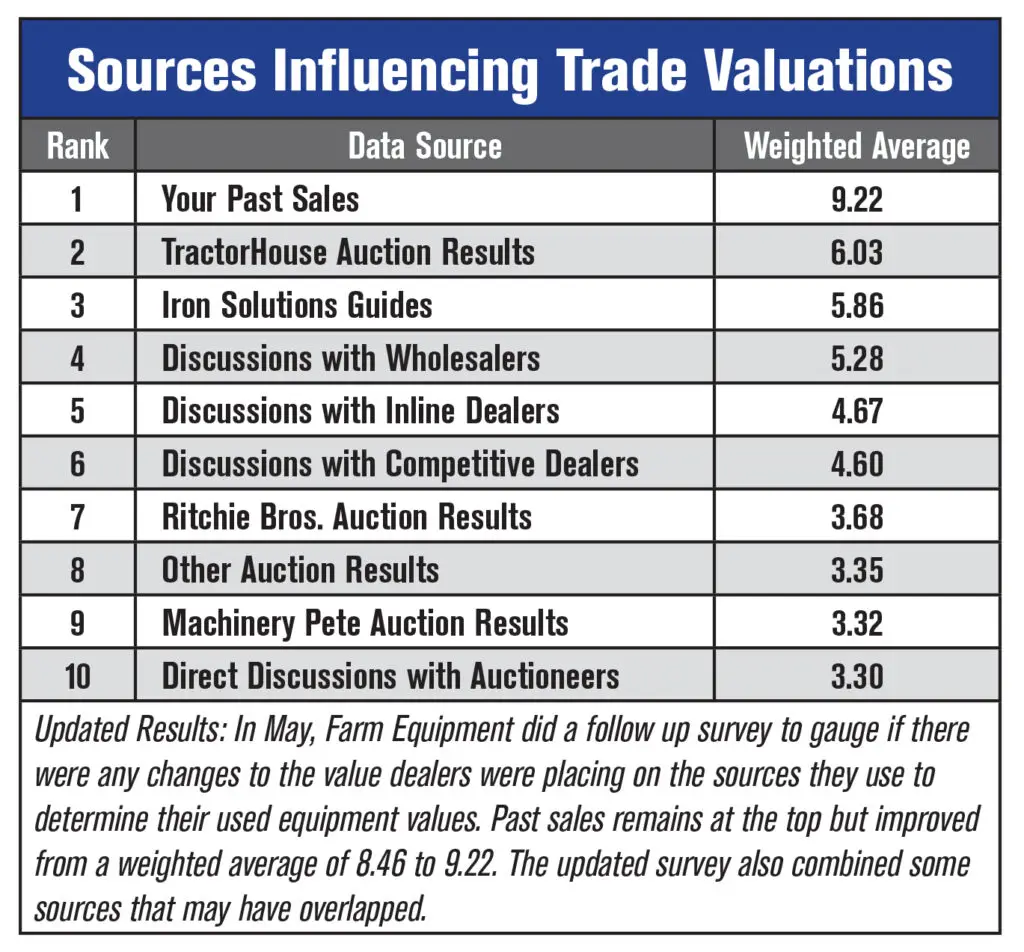

Research the current market value of similar farm equipment to ensure you have a baseline for evaluating the price. Websites, industry publications, and local dealerships can provide valuable information on market values and trends. Understanding the fair market value will help you negotiate a reasonable price and ensure you are making a sound investment.

10.2 Age and Condition

Consider the age and condition of the equipment when evaluating its price. Older equipment may come with a lower price tag, but it is crucial to assess its overall condition and potential longevity. A well-maintained piece of older equipment can still offer excellent value, while a newer unit with significant wear may not be worth the premium price.

10.3 Depreciation

Factor in the equipment’s depreciation over time when evaluating its price. Farm equipment is subject to depreciation due to age, usage, and technological advancements. Understanding the typical rate of depreciation will help you recognize a fair price and determine if the equipment is priced reasonably based on its depreciated value.

10.4 Comparable Sales

Consider recent comparable sales of similar farm equipment to determine if the asking price is fair and reflective of its overall condition. Compare the equipment’s specifications, age, condition, and included attachments to similar units that have recently been sold. Analyzing comparable sales data provides valuable insights into market demand and fair pricing.

This image is property of blog.ritchiebros.com.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.