This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

If you’re a farmer looking to improve your harvest efficiency, then choosing the right type of thresher for your farm is crucial. With so many options available on the market, it can be overwhelming to find the one that fits your specific needs. However, fear not! In this article, we will guide you through the process of selecting the perfect thresher for your farm, taking into consideration factors such as crop type, harvest volume, and budget. By the end, you’ll be equipped with the knowledge to make an informed decision and take your farming operations to the next level.

Factors to Consider when Choosing a Thresher

When choosing a thresher for your farm, there are several important factors to consider. Each factor is essential in determining the best type of thresher to meet your specific needs and requirements. By taking each of these factors into account, you can ensure that you select a thresher that not only efficiently threshes your crops but also fits within your budget and provides ease of use and maintenance. Let’s explore each of these factors in more detail.

Type of Crop

The type of crop you are growing is a crucial factor to consider when choosing a thresher. Different crops may require different types of threshers to achieve optimal results. Some crops may have tougher grains, while others may have a higher moisture content. Understanding the characteristics of your crop will help you determine which type of thresher is suitable for effectively threshing the crop without causing damage.

Crop Yield

The crop yield, or the amount of crop you expect to harvest, is another factor to consider. If you have a smaller farm with a limited crop yield, a smaller and more compact thresher may be sufficient for your needs. On the other hand, if you have a larger farm with a significant crop yield, you may need a more powerful and efficient thresher to handle the workload effectively.

Farm Size

The size of your farm plays a significant role in selecting the right thresher. If you have a smaller farm, you may prefer a thresher that is compact and easy to maneuver within tight spaces. Conversely, if you have a larger farm with ample storage and workspace, you may have more flexibility in choosing a thresher with a larger capacity.

Budget

Your budget is a vital consideration when choosing a thresher. Threshers come in a wide range of prices, depending on their type, size, and capabilities. It is essential to establish a budget and determine what features and capabilities are most important to you. This will help you narrow down your options and select a thresher that offers the best value for your money.

Power Source

The power source of a thresher can vary, with options including electric, gasoline, diesel, or even manual operation. Consider the availability and cost of the power source in your area, as well as your familiarity and comfort with the different options. Electric threshers may be more convenient if you have access to reliable electricity, while gasoline or diesel-powered threshers may be preferable in areas with limited electrical infrastructure.

Cleaning and Maintenance

Threshers need regular cleaning and maintenance to ensure optimal performance and longevity. Consider the ease of cleaning and maintaining the thresher you are considering. Look for features such as easy access to critical components, user-friendly maintenance procedures, and the availability of replacement parts. A thresher that is easy to clean and maintain will save you time and effort in the long run.

Availability of Parts

When investing in a thresher, it is essential to consider the availability of parts. It is inevitable that some parts may wear out or require replacement over time. Ensure that the thresher you choose has a reliable supply of replacement parts. You don’t want to be left without a functioning thresher due to the unavailability of necessary spare parts.

Ease of Use

Selecting a thresher that is easy to use is of utmost importance. Consider the user interface, controls, and overall design of the thresher. Look for features such as intuitive controls, clear instructions, and ergonomic design that will make operating the thresher straightforward and efficient. An easy-to-use thresher will not only enhance your productivity but also reduce the risk of operator error and accidents.

Storage

Storage considerations should not be overlooked when choosing a thresher. Threshers come in various sizes, and you need to ensure that you have adequate storage space to accommodate the thresher when it is not in use. Take measurements of your storage area and compare them to the dimensions of the thresher you are considering to ensure a proper fit.

Warranty

Finally, don’t forget to check the warranty offered by the thresher manufacturer. A thresher is a significant investment, and a comprehensive warranty will provide you with peace of mind. Review the warranty terms and conditions, including the duration and coverage, to ensure that you are adequately protected in case of any manufacturing defects or issues.

This image is property of static.agriculture-machine.com.

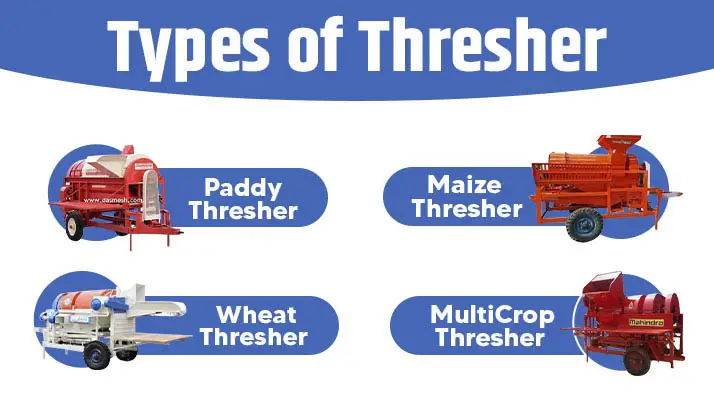

Types of Threshers

Now that we have explored the factors to consider when choosing a thresher, let’s take a look at the different types of threshers available in the market:

Drum Threshers

Drum threshers are one of the most common types of threshers. They consist of a rotating drum with concave surfaces that separate the grains from the crop. Drum threshers are versatile and can handle a wide range of crops, making them a popular choice for many farmers.

Hammer Mill Threshers

Hammer mill threshers use powerful hammers or blades to beat the crop, separating the grains from the stalk. These threshers are efficient and suitable for crops with larger grains or strong fibers. Hammer mill threshers are often used for threshing maize, rice, and sorghum.

Spike Tooth Threshers

Spike tooth threshers have rows of sharp metal teeth that rotate to remove the grains from the crop. They are particularly effective for crops with smaller grains, such as barley or wheat. Spike tooth threshers are known for their high threshing efficiency and low grain breakage.

Wire Loop Threshers

Wire loop threshers consist of rotating wire loops that remove the grains from the crop. These threshers are commonly used for crops with delicate grains or those prone to breakage, such as oats or legumes. Wire loop threshers provide gentle threshing to minimize grain damage.

Axial Flow Threshers

Axial flow threshers use a combination of axial and centrifugal airflow to separate the grains from the crop. These threshers are highly efficient and suitable for crops with a high moisture content or those that require gentle threshing. Axial flow threshers are often used for crops such as soybeans, sunflowers, or pulses.

Now that you have a better understanding of the factors to consider and the types of threshers available, you can make an informed decision based on your specific farm requirements. Remember to assess each factor carefully and prioritize your needs to select a thresher that will be a valuable asset to your farming operation. Happy threshing!

This image is property of www.tractorjunction.com.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.