This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

So, you’ve found yourself in possession of a combine harvester and you’re not quite sure where to begin. Don’t worry, operating this powerful piece of machinery may seem daunting at first, but with a little guidance, you’ll be harvesting crops like a pro in no time. In this article, we’ll take you through a step-by-step process, providing you with the basic knowledge and skills needed to efficiently operate a combine harvester. Get ready to embrace the world of agricultural machinery and become the master of the harvest!

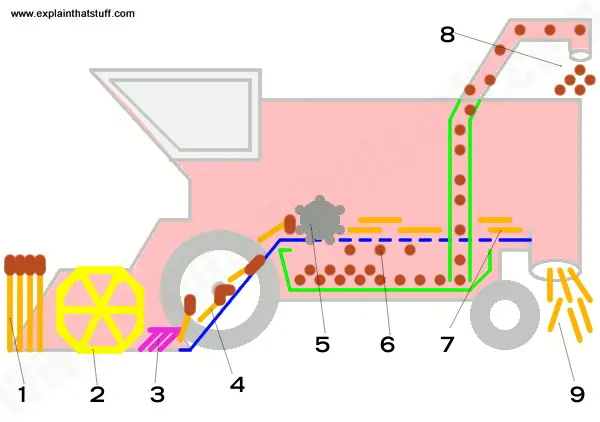

This image is property of cdn4.explainthatstuff.com.

Preparation

Before operating a combine harvester, there are several important steps you need to take to ensure a successful and safe experience.

Check the operator’s manual

First and foremost, familiarize yourself with the operator’s manual for the specific make and model of the combine harvester you will be using. The manual will provide detailed instructions and safety guidelines that are specific to your machine. Take the time to read through it thoroughly so you have a good understanding of how the harvester works.

Inspect the combine harvester

Next, conduct a thorough inspection of the combine harvester. Check for any signs of damage, loose or worn parts, or leaks. It is important to address any issues before starting the machine to prevent further damage or safety hazards. Pay close attention to the cutting system and header, as well as the engine and controls.

Familiarize yourself with the controls

Take the time to familiarize yourself with the controls of the combine harvester. This includes understanding the functions of each button, lever, and switch. Knowing how to operate the controls with ease will make your job much easier and minimize the risk of accidents. Practice using the controls before you begin to gain confidence and ensure smooth operation.

Check fuel and lubricants

Before starting the combine harvester, check the fuel and lubricants. Ensure that there is enough fuel to complete the harvesting task and that the oil and grease levels are at the recommended levels. It is also important to check the condition of the engine air filter and clean or replace it if necessary. Properly lubricated and fueled machinery will operate more efficiently and reliably.

Starting the Combine Harvester

Now that you have completed the necessary preparations, it’s time to start the combine harvester and get ready for operation.

Ensure safety precautions

Before starting the combine harvester, make sure you are wearing appropriate Personal Protective Equipment (PPE). This includes safety glasses, ear protection, and sturdy footwear. Be aware of your surroundings and ensure that others are at a safe distance from the machine. Remember, safety should always be your top priority.

Engage the parking brake

Before starting the engine, engage the parking brake to prevent any unwanted movement of the harvester. This will ensure that the machine remains stationary while you go through the starting procedure.

Start the engine

Once the parking brake is engaged, start the engine according to the manufacturer’s instructions. Allow the engine to idle for a few minutes to warm up before moving on to the next step. Pay attention to the engine gauges and indicators to ensure that everything is functioning properly.

Monitor gauges and indicators

While the engine is running, keep an eye on the gauges and indicators to monitor the condition of the machine. This includes watching the oil pressure, coolant temperature, and fuel level. If any of these indicators are outside of the recommended range, take the necessary steps to address the issue before proceeding.

Release the parking brake

Once you have ensured that the engine is running smoothly and all gauges are within the appropriate ranges, it’s time to release the parking brake. Check for any unwanted movement before proceeding to the next steps.

Operating the Combine Harvester

With the combine harvester started and ready for operation, it’s time to get into the field and start harvesting.

Adjust the cutting height

Before engaging the header, adjust the cutting height to the appropriate level for the crop you are harvesting. This can vary depending on the crop and its stage of growth. Consult the operator’s manual for specific recommendations on cutting height for various crops. Adjusting the cutting height ensures that you are harvesting the crop at the optimal level, maximizing yield and quality.

Engage the header

Once the cutting height is set, engage the header. This will activate the cutting system and start harvesting the crop. Ensure that the header is properly aligned and that all guards and features are in place and functioning correctly.

Set the ground speed

As you begin harvesting, it is important to set the ground speed at a pace that allows for efficient and effective operation. The ideal speed will depend on the crop conditions and the terrain. Be mindful of the crop flow and adjust the speed accordingly to prevent crop loss or damage.

Monitor the crop flow

While operating the combine harvester, it is crucial to continuously monitor the crop flow. Pay attention to any signs of crop clogs, such as abnormal noises or changes in the machine’s performance. Clear any blockages immediately to prevent damage to the combine harvester and ensure uninterrupted harvesting.

Adjust the header speed

Depending on the crop conditions and the specific requirements of the crop being harvested, you may need to adjust the header speed. This can help optimize performance and prevent excessive crop loss or damage. Experiment with different speeds to find the most efficient setting for the specific crop and field conditions.

Manage the unloading process

As the combine harvester fills up with harvested crop, it will need to be emptied. Familiarize yourself with the unloading process and make sure you are familiar with the location of the grain tank and how to safely unload it. Take care to avoid any unloading hazards and ensure that the harvested crop is properly stored.

Harvesting Techniques

The success of your harvesting operation is highly dependent on employing the right techniques for each crop. Here are some key considerations for a successful harvest.

Identify the right crop stage

To achieve optimal yield and quality, it is essential to harvest the crop at the right stage of maturity. Consult local agricultural resources or experts to determine the appropriate stage of harvest for different crops. Harvesting too early or too late can result in yield loss or poor-quality grain.

Choose the correct header type

Different crops require different header types for effective harvesting. Ensure that you have the correct header for the crop you are harvesting. The header should be properly adjusted and aligned to ensure efficient crop flow and minimal losses.

Select the appropriate harvesting method

There are various harvesting methods available, depending on the crop and field conditions. These may include direct cutting, swathing, or windrowing. Consider the crop characteristics, weather conditions, and agronomic practices when selecting the appropriate method for each crop.

Optimize header and reel settings

The header and reel settings play a crucial role in capturing the crop effectively and minimizing losses. Adjust the header height and angle to ensure that the crop is properly cut and gathered. The reel speed may need to be adjusted based on the crop conditions, such as crop height and density.

Adjust concave clearance

The concave clearance is a critical parameter that determines the threshing and separation of the grain from the crop. Adjusting the concave clearance can help optimize grain quality and reduce losses. Consult the operator’s manual for specific recommendations on concave clearance for different crops.

Monitor grain and straw quality

While harvesting, closely monitor the quality of the harvested grain and straw. This includes checking for signs of damage, foreign materials, or excessive moisture. Make adjustments as needed to minimize grain damage and maximize overall harvest quality.

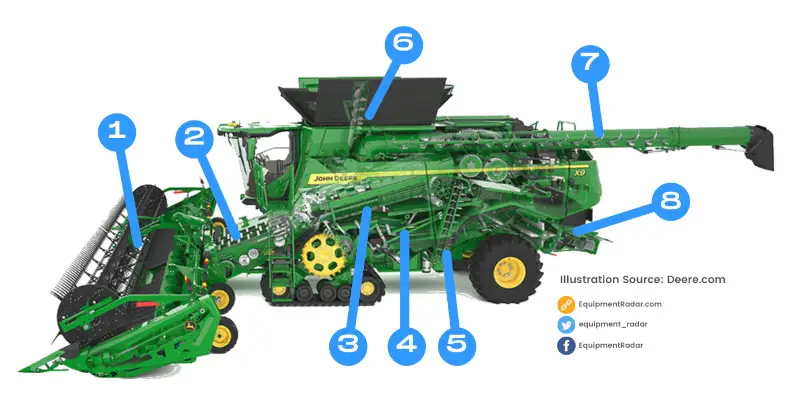

This image is property of cdn.equipmentradar.com.

Handling Different Crops

Different crops require specific considerations for successful harvesting. Let’s explore some key factors for handling popular crops with a combine harvester.

Wheat

When harvesting wheat, it is important to adjust the combine harvester settings to ensure an efficient harvest. Optimal header speed and reel settings play a crucial role in capturing the wheat without excessive losses. Adjust the fan speed and sieve settings to control the distribution of chaff and straw.

Corn

Corn harvesting requires specific considerations due to the size and density of the crop. Adjust the combine harvester for corn by using the appropriate corn header and adjusting the settings for stalk and cob damage. Monitor the moisture content of the corn and make adjustments to the harvesting speed and settings accordingly.

Soybeans

Soybeans can be challenging to harvest due to their delicate nature. Use a flexible cutterbar header to minimize crop losses. Adjust the combine harvester’s settings to handle the soybean plants gently and minimize pod shattering. Monitor the shelling and threshing processes to ensure optimal grain quality.

Barley

Barley is typically harvested at a higher moisture content than other small grains. Adjust the combine harvester settings to handle the higher moisture content, including properly adjusting the cylinder speed and concave clearance. Monitor the grain quality closely to prevent excessive losses or grain damage.

Rapeseed

Rapeseed harvesting requires attention to detail to minimize losses and ensure high-quality oilseeds. Adjust the combine harvester to accommodate the small size and shatter-prone nature of rapeseed pods. Monitor the cleaning process to separate the seeds effectively from the straw and chaff.

Troubleshooting

Even with proper preparation and maintenance, issues may arise while operating a combine harvester. Here are some common troubleshooting techniques.

Identifying common issues

When encountering issues with the combine harvester, take the time to identify the problem. This can include recognizing unusual noises, changes in performance, or warning indicators. Consult the operator’s manual or seek expert advice to determine the best course of action.

Checking sensor functionality

Modern combine harvesters often come equipped with sensors that monitor various aspects of the machine’s performance. If you suspect a sensor issue, check the functionality of the affected sensors. Ensure that the sensors are clean, properly connected, and calibrated.

Cleaning the combine harvester

A clean combine harvester operates more efficiently and minimizes the risk of issues. Regularly clean the machine, paying attention to areas prone to debris buildup, such as the cutting system, sieves, and chaff spreaders. Remove any lodged crop material or foreign objects to prevent clogs and damage.

Repairing minor mechanical faults

In some cases, minor mechanical faults can be resolved without professional assistance. Consult the operator’s manual for guidance on common mechanical issues and the steps required to address them. However, if you are unsure or the issue persists, it is best to seek professional assistance to avoid further damage.

Seeking professional assistance

For major or complex issues, it is crucial to seek professional assistance. Professional technicians have the expertise and tools to diagnose and repair significant problems effectively. Do not attempt to repair complex issues if you are not trained or experienced in handling them.

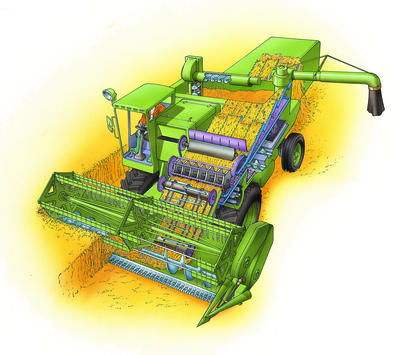

This image is property of i.ytimg.com.

Safety Considerations

Operating a combine harvester involves working with heavy machinery and potential hazards. Here are some safety considerations to keep in mind.

Wearing appropriate Personal Protective Equipment (PPE)

Always wear the appropriate Personal Protective Equipment (PPE) when operating a combine harvester. This includes safety glasses, ear protection, gloves, and sturdy footwear. PPE helps protect you from potential injuries and enhances your safety while working.

Avoiding loose clothing and jewelry

Avoid wearing loose clothing and jewelry while operating the combine harvester. Loose clothing can get caught in moving parts, leading to accidents or injuries. Remove jewelry or ensure it is securely fastened to prevent entanglement.

Using caution when working near moving parts

Exercise extreme caution when working near moving parts of the combine harvester. Avoid reaching into any moving components or attempting to clear clogs while the machine is running. Always wait for the machine to come to a complete stop and engage appropriate safety measures before approaching moving parts.

Practicing proper fire prevention measures

Combine harvesters can pose a fire risk, particularly in dry and dusty conditions. Practice proper fire prevention measures, such as regular cleaning to remove crop residue and debris. Carry a fire extinguisher with you and know how to use it effectively in case of an emergency.

Being aware of potential hazards

Always be aware of your surroundings and potential hazards when operating a combine harvester. Be cautious of uneven terrain, low-hanging obstacles, and overhead power lines. Maintain a safe distance from bystanders, particularly children and animals, to minimize the risk of accidents or injuries.

Maintenance and Storage

Proper maintenance and storage of the combine harvester are essential for its long-term performance and reliability. Here are some key maintenance practices to follow.

Regular cleaning

Regularly clean the combine harvester to remove crop residues, dirt, and debris. Pay attention to critical areas, such as the cutting system, sieves, and cooling system, to ensure optimal performance. Cleaning the combine harvester after each use will also help prevent the buildup of corrosive materials.

Greasing and lubrication

Proper greasing and lubrication of the combine harvester’s components are vital for smooth operation and preventing excessive wear. Follow the manufacturer’s recommendations for greasing intervals and use the appropriate lubricants. Regularly inspect the greasing points to ensure that they are properly lubricated.

Inspecting belts, chains, and sprockets

Regularly inspect the belts, chains, and sprockets of the combine harvester for signs of wear or damage. Replace any components that show excessive wear or are not functioning properly. Preventive maintenance of these components will reduce the risk of unexpected breakdowns during harvesting.

Draining fuel and fluids for storage

When the harvesting season comes to an end, it is important to properly prepare the combine harvester for storage. Drain the fuel and fluids according to the manufacturer’s recommendations to prevent any potential damage. Proper fuel and fluid management will extend the machine’s lifespan and prevent contamination.

Covering and protecting the combine harvester

Finally, cover and protect the combine harvester when it is not in use. This helps to prevent any damage from weather elements, such as rain or excessive sunlight. Store the machine in a clean, dry, and secure location to minimize the risk of theft or vandalism.

This image is property of gridclub.com.

Upgrading and Modernizing

As technology advances, there may come a time when you consider upgrading or modernizing your combine harvester. Here are some factors to consider.

Considerations before upgrading

Before upgrading your combine harvester, carefully evaluate your specific needs and requirements. Consider factors such as crop types, field conditions, and desired harvest capacity. Research and consult with experts to determine if upgrading is the best option for your specific situation.

Improving technology and automation

Upgrading your combine harvester can introduce advanced technology and automation features that improve efficiency and productivity. This may include features such as yield mapping, automatic header height control, or data management systems. Assess the benefits of these technologies and determine if they align with your goals.

Optimizing efficiency and yield

Modern combine harvesters often offer improved efficiency and yield potential compared to older models. Upgrading to a more efficient and high-yielding combine harvester can result in increased productivity and profitability. Calculate the potential return on investment before making a decision.

Conclusion

Operating a combine harvester may seem daunting at first, but with proper preparation and understanding, you can confidently tackle the task. By following the outlined steps for preparation, starting the machine, operating it effectively, and considering specific harvesting techniques for different crops, you can ensure a successful harvest. Remember to prioritize safety, perform regular maintenance, and consider upgrading or modernizing when appropriate. With these practices in place, you will be able to operate your combine harvester with confidence and achieve optimal results in your harvests.

This image is property of blog.machinefinder.com.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.