This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

Maintaining the cooling system of your farm machinery is essential to ensure that your equipment runs smoothly and efficiently. By regularly checking for any signs of damage or leaks, cleaning the radiator and coolant reservoir, and replacing the coolant at recommended intervals, you can prevent costly breakdowns and maximize the lifespan of your machinery. In this article, we will explore some simple yet effective tips to help you maintain the cooling system of your farm machinery in top-notch condition. Whether you’re a seasoned farmer or just starting out, these maintenance techniques will surely keep your equipment operating at its best, allowing you to focus on the tasks at hand without any worries.

Importance of Cooling System Maintenance

Proper maintenance of the cooling system in your farm machinery is crucial for several reasons. First and foremost, it helps prevent overheating, which can lead to costly repairs and downtime. By regularly inspecting and maintaining your cooling system, you can ensure that your machinery operates at optimal performance and efficiency. Additionally, proper cooling system maintenance helps prolong the lifespan of your farm machinery, saving you money in the long run.

Regular Inspection Routine

To maintain the cooling system of your farm machinery, it is important to establish a regular inspection routine. This routine should include checking the coolant level, inspecting for leaks, and examining the radiator’s condition.

Checking Coolant Level

Regularly monitoring the coolant level is essential to ensure proper cooling system function. Low coolant levels can cause the engine to overheat and potentially damage other components. Check the coolant level when the engine is cool and add more if necessary, following the manufacturer’s recommendations.

Inspecting for Leaks

Inspecting your farm machinery for coolant leaks is crucial, as even small leaks can lead to significant coolant loss over time. Look for any signs of fluid dripping or pooling under your machinery. Additionally, visually inspect all hoses and fittings for cracks, wear, or loose connections. Address any leaks promptly to prevent serious damage to your machinery.

Examining Radiator Condition

A thorough examination of the radiator can help detect any potential issues early on. Look for any signs of damage, such as bent fins or corrosion. If the radiator appears dirty or clogged, it may require cleaning or replacement. Regularly inspecting the radiator ensures proper airflow and optimal cooling performance.

This image is property of cdn.dealerspike.com.

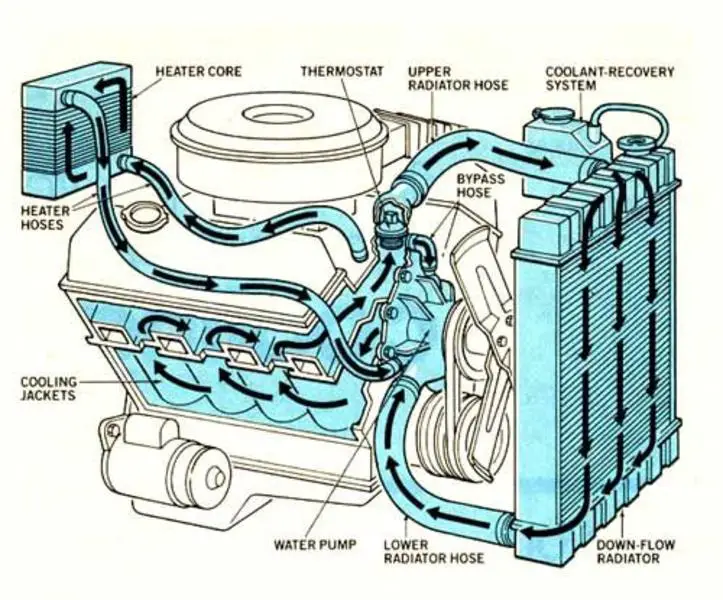

Flushing and Refilling the Cooling System

Another essential aspect of cooling system maintenance is flushing and refilling the system. Over time, coolant can become contaminated with debris, rust, and sediment, reducing its effectiveness. Flushing the system removes these contaminants, ensuring that fresh coolant can circulate properly.

Draining the Old Coolant

To flush the cooling system, start by draining the old coolant. Consult your machinery’s manual for specific instructions on how to drain the coolant. Make sure to use a proper container to collect the coolant, as it is toxic and should be disposed of correctly. Once all the old coolant has been drained, move on to the next step of the flushing process.

Flushing the System

After draining the old coolant, it is time to flush the system. Use a coolant flush solution or a mixture of distilled water and radiator cleaner, following the manufacturer’s instructions. This solution will help remove any remaining contaminants from the system. Once the solution has circulated through the system, drain it following the same process as before.

Refilling with Fresh Coolant

After flushing the system, it is important to refill it with fresh coolant. Use a high-quality coolant recommended by the manufacturer to ensure optimal performance. It is also crucial to maintain the correct coolant-to-water ratio, as specified by the manufacturer. Carefully pour the coolant into the radiator while the engine is cool, and check the coolant level to ensure it reaches the recommended level.

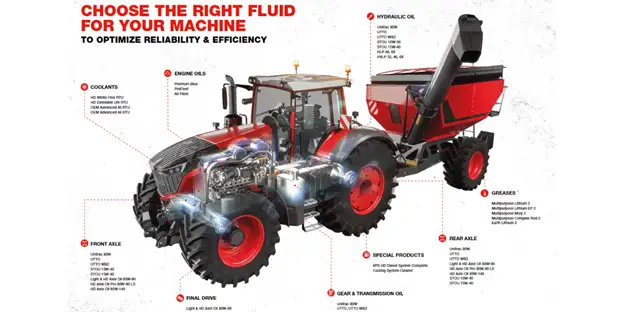

Proper Coolant Selection

Choosing the right coolant for your farm machinery is essential for maintaining an efficient and effective cooling system. There are various types of coolant available, including ethylene glycol-based and propylene glycol-based coolants. It is crucial to select the coolant that is compatible with your machinery’s requirements and climate conditions.

Choosing the Right Type of Coolant

Different types of farm machinery may require different types of coolant. Refer to your machinery’s manual or consult with a professional to determine the appropriate coolant type. Factors to consider include the machinery’s age, engine design, and operating conditions. Choosing the right coolant type ensures optimal performance and longevity of the cooling system.

Checking for Compatibility

In addition to selecting the right type of coolant, it is essential to ensure that it is compatible with your machinery’s components. Some coolant formulations may not be suitable for certain materials, such as aluminum or brass. Check the coolant label for information on compatibility with different metals and materials to avoid any potential damage.

Maintaining the Correct Coolant-to-Water Ratio

Maintaining the correct coolant-to-water ratio is crucial for optimal performance and protection against freezing or overheating. Follow the manufacturer’s recommendations for the specific coolant-to-water ratio. Using a higher concentration of coolant than recommended can result in reduced heat transfer and, conversely, using too much water can lead to freezing or boiling issues.

This image is property of www.valvolineglobal.com.

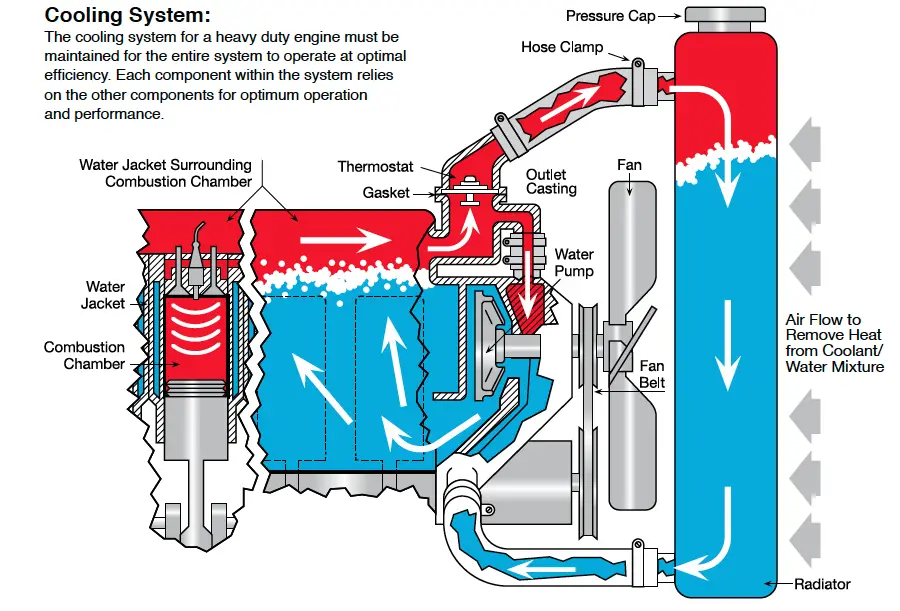

Cleaning and Maintaining Radiator

The radiator is a critical component of the cooling system, responsible for dissipating heat. Keeping it clean and well-maintained is essential for optimal cooling system performance.

Removing Debris and Dirt

Regularly clean the radiator to remove any debris, dirt, or insects that may be obstructing airflow. Use a soft brush or compressed air to gently remove any buildup on the radiator fins. Be careful not to damage the fins, as bent fins can restrict airflow and reduce cooling efficiency.

Inspecting for Bent Fins

Bent fins can significantly impact the radiator’s ability to dissipate heat. Periodically inspect the radiator for any bent or damaged fins. If you notice any, use a fin straightening tool or a flat-head screwdriver to carefully straighten them. Ensuring that the radiator fins are straight allows for optimal airflow and efficient cooling.

Using Restrictions to Optimize Cooling

In some cases, using restrictions in the cooling system can help optimize cooling efficiency. These restrictions, such as radiator caps with lower pressure ratings, can increase the boiling point of the coolant and improve overall cooling performance. Consult with a professional or refer to your machinery’s manual to determine if using restrictions is suitable for your specific cooling system.

Maintaining Fan and Fan Belt

The fan and fan belt play a vital role in maintaining proper airflow and cooling system performance. Regular maintenance of these components is essential to prevent overheating issues.

Checking Fan Blades for Damage

Inspect the fan blades for any signs of damage, such as cracks or chips. Damaged fan blades can lead to imbalanced airflow and reduced cooling efficiency. If you notice any damage, it is important to replace the fan immediately to avoid further problems.

Tensioning the Fan Belt

Proper tension of the fan belt is crucial for ensuring that the fan operates at the correct speed. Over time, the fan belt can become loose, affecting cooling system performance. Check the tension of the fan belt regularly and adjust it if necessary. Refer to your machinery’s manual for specific instructions on how to properly tension the fan belt.

Lubricating Fan Bearings

Regularly lubricating the fan bearings helps prevent friction and ensures smooth operation. Use a high-quality lubricant recommended by the manufacturer and apply it to the fan bearings according to the specified intervals. Proper lubrication reduces wear and tear on the fan bearings, prolonging their lifespan and maintaining optimal cooling efficiency.

This image is property of www.trucknews.com.

Inspecting Hoses and Belts

The hoses and belts in your farm machinery’s cooling system play a crucial role in transporting coolant and driving various components. Regular inspection of these components is necessary to identify any signs of wear or damage.

Checking for Cracks or Bulges

Inspect all hoses for any signs of cracks, bulges, or leaks. Hoses that are damaged or deteriorated can lead to coolant leaks or even complete hose failure. If you notice any issues, it is essential to replace the hoses promptly to prevent any potential damage to your machinery.

Confirming Proper Tightness

Ensure that all hoses and belts are properly tightened. Loose connections can result in coolant leaks or decreased cooling efficiency. Regularly check the tightness of hose clamps and belt tensioners and make any necessary adjustments.

Replacing Worn-out Hoses or Belts

If you notice any hoses or belts that are worn-out, damaged, or nearing the end of their lifespan, it is crucial to replace them promptly. Operating your farm machinery with worn-out hoses or belts can lead to coolant leaks, overheating, or even more severe damage. Keep spare hoses and belts on hand to minimize downtime and ensure a quick replacement when needed.

Monitoring Temperature and Pressure

Monitoring the temperature and pressure in your farm machinery’s cooling system is essential for early detection of any abnormalities or potential issues.

Using Temperature Gauge

Regularly monitor the temperature gauge on your machinery’s dashboard. Abnormally high temperatures could indicate cooling system problems, such as a malfunctioning thermostat, coolant leaks, or a failing radiator. If you notice any significant fluctuations or consistently high temperatures, it is important to address the issue promptly to prevent further damage.

Checking Pressure Levels

Monitoring the pressure levels in your cooling system can provide valuable information about its overall health. Using a pressure gauge, check the pressure in the system when it is cool and compare it to the manufacturer’s recommended levels. Any significant deviations from the recommended pressure may indicate a problem, such as a faulty pressure cap or a leak in the system.

Addressing Abnormalities

If you observe any abnormal temperature or pressure readings, it is important to take immediate action. Investigate the cause of the abnormality or seek professional assistance if necessary. Addressing abnormalities promptly can help prevent further damage to your farm machinery and cooling system.

This image is property of www.tractorjunction.com.

Preventing Coolant Contamination

Proper coolant maintenance includes measures to prevent coolant contamination, ensuring that it remains effective in protecting your machinery’s cooling system.

Using Clean Water Sources

When topping up your coolant or performing a coolant flush, it is crucial to use clean water sources. Clean, distilled water is the best option to prevent introducing contaminants into the cooling system. Avoid using tap water or water from unknown sources, as they may contain minerals or impurities that can affect coolant performance.

Avoiding Mixing Coolants

Mixing different types of coolants can lead to chemical reactions and reduced effectiveness. Always use the same type of coolant or ensure compatibility if switching to a different coolant formulation. Refer to your machinery’s manual or consult with a professional to determine the appropriate coolant for your specific system.

Eliminating Air Pockets

Air pockets in the cooling system can disrupt coolant flow and lead to overheating or uneven cooling. When refilling the cooling system, take care to eliminate any trapped air by properly bleeding the system. Follow the manufacturer’s instructions or consult with a professional to ensure proper air pocket elimination procedures.

Seeking Professional Assistance

While regular maintenance can be performed by owners or operators, seeking professional assistance is highly recommended for comprehensive and thorough cooling system maintenance.

Annual Servicing by Certified Technicians

Schedule an annual servicing of your farm machinery’s cooling system by certified technicians. These professionals have the skills and knowledge to perform in-depth inspections, identify potential issues, and conduct necessary repairs or replacements. Regular professional servicing ensures that your cooling system remains in top condition and minimizes the risk of major breakdowns.

Diagnostic Testing

If you notice any persistent issues, abnormal readings, or performance problems with your cooling system, it is essential to seek professional diagnostic testing. These tests can help identify underlying issues that may not be immediately apparent, allowing for timely repairs or component replacements.

Repairing and Replacing Faulty Components

In cases where cooling system components are damaged or malfunctioning, it is crucial to repair or replace them promptly. Attempting to repair or replace components without the necessary expertise can result in further damage or improper installation. Rely on the skills and knowledge of professional technicians to ensure that faulty components are addressed correctly and efficiently.

In conclusion, properly maintaining the cooling system of your farm machinery is essential for preventing overheating, improving performance and efficiency, and prolonging the machinery’s lifespan. Establishing a regular inspection routine, flushing and refilling the cooling system, selecting the proper coolant, cleaning and maintaining the radiator, and inspecting hoses and belts are all essential maintenance steps. Additionally, monitoring temperature and pressure, preventing coolant contamination, and seeking professional assistance when needed are crucial for ensuring optimal cooling system function. By prioritizing cooling system maintenance, you can minimize downtime, reduce repair costs, and maximize the efficiency and lifespan of your farm machinery.

This image is property of khetigaadi.com.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.