This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

Maintaining the electrical system of your farm machinery is essential to ensure smooth operations and prevent any unexpected breakdowns. From tractors to irrigation equipment, every piece of machinery relies on a well-functioning electrical system. In this article, we will walk you through some simple yet effective tips and techniques to help you properly maintain the electrical system of your farm machinery. By following these guidelines, you can minimize downtime, increase efficiency, and ultimately maximize productivity on your farm.

Importance of Maintaining the Electrical System

Maintaining the electrical system of your farm machinery is of utmost importance, as it plays a crucial role in ensuring efficient operation, reducing the risk of breakdowns, and increasing the lifespan of your machinery. By implementing regular inspections, cleaning routines, and following proper storage and maintenance practices, you can ensure that your electrical system remains in optimal condition.

Regular Inspection and Cleaning

Regular inspections and cleaning of your farm machinery’s electrical system are essential to identify any potential issues and prevent them from escalating into major problems. During these inspections, it is important to check for loose connections, as these can lead to power interruptions and even short circuits. Loose connections can cause significant damage to the machinery and may result in costly repairs.

Additionally, cleaning the battery terminals is crucial, as dirt and corrosion can build up over time and hinder the battery’s performance. By regularly cleaning the terminals, you can maintain a strong connection, ensure proper charging, and extend the battery’s lifespan. Furthermore, inspecting the wiring for any signs of damage, such as frayed or exposed wires, is vital to avoid potential hazards and safeguard the overall system.

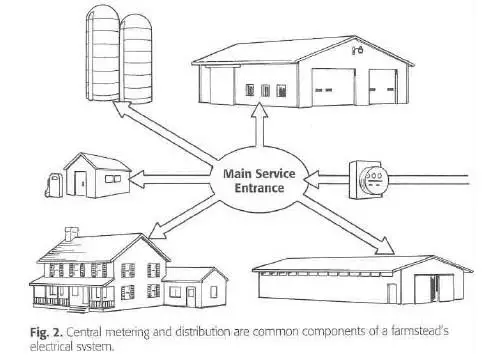

This image is property of nasdonline.org.

Proper Storage and Protection

Proper storage and protection of your farm machinery are vital factors in maintaining its electrical system. Storing the machinery in a dry location is essential to prevent moisture from seeping into the electrical components, which can result in corrosion, short circuits, and even complete electrical failure. Additionally, protecting the machinery from moisture and dust by using tarps or waterproof sheets can help prevent damage and ensure that the electrical system remains functional and reliable.

Battery Maintenance

The battery is a key component of the electrical system, and regular maintenance is essential to keep it in optimal condition. Checking the battery fluid levels on a regular basis is important, as low fluid levels can lead to reduced battery performance and shortened lifespan. By topping up the fluid as needed, you can ensure that the battery operates at its full potential.

Cleaning the battery terminals is another crucial maintenance task. Over time, corrosion can accumulate on the terminals, hindering the flow of electricity and causing the battery to weaken. By regularly cleaning the terminals, you can remove any buildup and maintain a strong connection, promoting efficient battery performance.

Furthermore, it is essential to charge the battery regularly, especially during periods of inactivity. A fully charged battery will not only ensure that your machinery starts smoothly but will also extend its overall lifespan.

This image is property of www.tractorjunction.com.

Protective Measures for Wiring

Properly protecting the wiring of your farm machinery is vital to prevent damage and maintain optimal operation. Securing the wiring with cable ties helps to keep it neat and organized, reducing the risk of tangling or snagging on other components. This ensures that the wiring remains intact and undamaged, promoting smooth electrical flow.

Using wire looms to protect the wiring is another important step. Wire looms prevent the wires from being exposed to abrasive surfaces or sharp edges, reducing the risk of cuts or breakages that could result in electrical malfunctions. Avoiding pinching or crimping of the wiring when installing or moving components is crucial, as these actions can damage the wires and compromise the electrical integrity of the system.

Maintenance of Fuses and Circuit Breakers

Regular inspection and maintenance of fuses and circuit breakers are essential for the continued safe and efficient operation of the electrical system in your farm machinery. Inspecting the fuses for any signs of damage, such as cracks or discoloration, is important. Damaged fuses should be replaced promptly to prevent electrical failures or potential hazards.

Blown fuses are a common occurrence and can indicate an underlying problem. If you notice blown fuses frequently, it is crucial to investigate the cause and address it promptly to prevent further damage. Additionally, testing circuit breakers periodically ensures that they are functioning correctly and can effectively protect the electrical system from overload or short circuits.

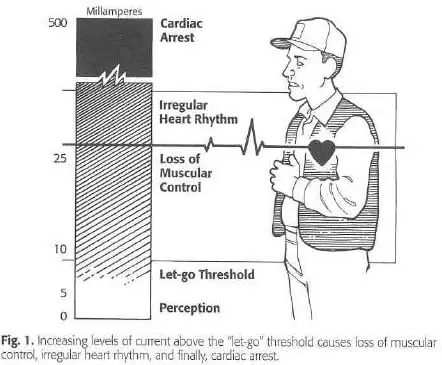

This image is property of www.pequea.com.

Alternator and Starter Motor Maintenance

The alternator and starter motor play vital roles in the electrical system of your farm machinery. Regular maintenance of these components is crucial to ensure their proper operation and prevent unexpected breakdowns. Checking the belt tension and condition of the alternator is important, as loose or worn-out belts can lead to slipping or insufficient charging. Adjusting or replacing the belts as necessary will ensure that the alternator functions optimally.

Cleaning and tightening connections on the alternator and starter motor are important maintenance tasks. Over time, dirt and corrosion can accumulate on these components, impeding their performance. By cleaning them regularly and ensuring secure connections, you can maintain efficient electrical flow and extend the lifespan of these critical components. Testing and replacing any faulty components promptly is also essential to avoid unexpected failures when starting the machinery.

Proper Usage of Electrical Accessories

Using electrical accessories correctly is vital for the overall health of your farm machinery’s electrical system. It is important to use accessories that are compatible with your machinery’s electrical specifications. Using incompatible accessories can overload the system, leading to electrical malfunctions or even damage to the machinery.

Avoiding overloading electrical circuits is crucial to prevent power fluctuations and potential damage to the system. Be mindful of the electrical load you are placing on the machinery and distribute it evenly across different circuits if necessary. Proper grounding is also essential to ensure the safety of both the machinery and the individuals operating it.

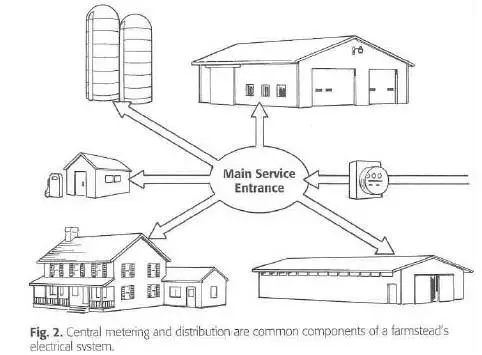

This image is property of nasdonline.org.

Protection from Rodents and Pests

Rodents and pests can cause significant damage to the electrical system of your farm machinery. To protect your machinery, it is important to seal possible entry points that may allow pests to enter. Pests can chew through wires, leading to electrical failures or even fire hazards. Using rodent deterrents in and around your machinery can help prevent these unwanted visitors, ensuring the continued functionality of your electrical system. Regularly inspecting for signs of damage, such as chewed wires or droppings, allows you to address any pest-related issues promptly.

Training and Safety Measures

Proper training and adherence to safety measures are crucial for the prevention of electrical hazards and the preservation of the electrical system in your farm machinery. Training personnel on electrical safety practices will enable them to handle and operate the machinery correctly, reducing the risk of accidents and damage. Following the manufacturer’s guidelines for maintenance and operation is essential, as they provide valuable insight into the proper care of the electrical system.

Using personal protective equipment (PPE), such as gloves and safety goggles, when inspecting or working on the electrical system adds an extra layer of protection. PPE helps prevent injuries and ensures the safety of the personnel involved in maintenance tasks.

In conclusion, maintaining the electrical system of your farm machinery is vital to ensure efficient operation, reduce the risk of breakdowns, and increase the lifespan of the machinery. By implementing regular inspections, cleaning routines, proper storage and maintenance practices, and adhering to safety measures, you can ensure the longevity and optimal performance of your machinery’s electrical system.

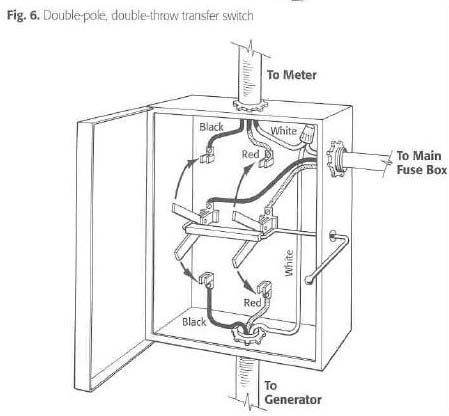

This image is property of nasdonline.org.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.