This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

Taking care of the engine in your farm machinery is crucial for optimal performance and durability. With regular maintenance, you can prevent costly repairs and ensure that your equipment runs smoothly during critical farming seasons. From checking the oil levels to cleaning air filters and inspecting fuel systems, this article will provide you with valuable tips and techniques to keep your farm machinery’s engine in top shape. So, let’s dive in and learn how to properly maintain the heart of your agricultural operations.

Regular Cleaning

Cleaning the Exterior

To properly maintain the engine of your farm machinery, it’s important to start with regular cleaning. Cleaning the exterior of your machinery is essential to remove dirt, dust, and debris that can accumulate over time. This can be done by using a hose or pressure washer to spray down the exterior surfaces. Pay special attention to the engine compartment, as this area tends to collect a lot of grime. Use a gentle detergent and a soft brush to scrub away any stubborn dirt. Rinse thoroughly and allow the machinery to dry completely before moving on to the next step.

Cleaning the Interior

In addition to cleaning the exterior, it’s also crucial to regularly clean the interior components of your farm machinery’s engine. This includes removing any debris or dirt that may have accumulated in the engine bay. Start by disconnecting the battery to ensure safety. Use compressed air or a vacuum cleaner to remove loose dust and debris from the engine compartment. Be careful not to damage any wiring or delicate components in the process. For stubborn dirt or grease, use a degreaser and a cloth to wipe down the surfaces. Make sure to thoroughly dry the interior before reconnecting the battery.

Cleaning the Filters

Another important aspect of engine maintenance is to clean the filters regularly. Filters, such as the air filter and fuel filter, play a crucial role in keeping the engine clean and running smoothly. Start by locating the filters in your farm machinery. Remove the filters according to the manufacturer’s instructions and inspect them for any signs of damage or clogging. If the filters are dirty, gently tap them to remove loose debris, or use compressed air to blow away the dirt. Avoid using water or harsh chemicals to clean the filters, as this can damage them. If the filters are beyond cleaning, it’s best to replace them with new ones to ensure optimal engine performance.

Regular Oil Changes

Checking the Oil Level

Routine oil changes are vital for maintaining the engine of your farm machinery. Start by checking the oil level regularly to ensure it is within the recommended range. Locate the oil dipstick, which is usually found near the engine bay. Remove the dipstick, wipe off any oil, and reinsert it fully. Remove it again and check the oil level against the markers on the dipstick. If the oil level is low, add the recommended type and amount of oil as specified in the owner’s manual. Be careful not to overfill, as this can lead to engine damage.

Draining the Old Oil

To maintain the engine’s health, it is important to change the oil at regular intervals. Start by running the machinery for a few minutes to warm up the oil, as warm oil flows more easily. Next, locate the oil drain plug underneath the machinery’s engine. Place a container to catch the oil underneath the drain plug. Carefully remove the plug, allowing the old oil to drain completely. Once all the old oil has drained, replace the drain plug securely to avoid any leaks.

Adding Fresh Oil

After draining the old oil, it’s time to add fresh oil to your farm machinery’s engine. Refer to the owner’s manual for the recommended type and amount of oil. Locate the oil filler cap, usually found on the top of the engine, and remove it. Use a funnel to pour the fresh oil into the engine, being careful not to spill any. Once you’ve added the oil, replace the oil filler cap securely. Remember to properly dispose of the old oil according to local regulations.

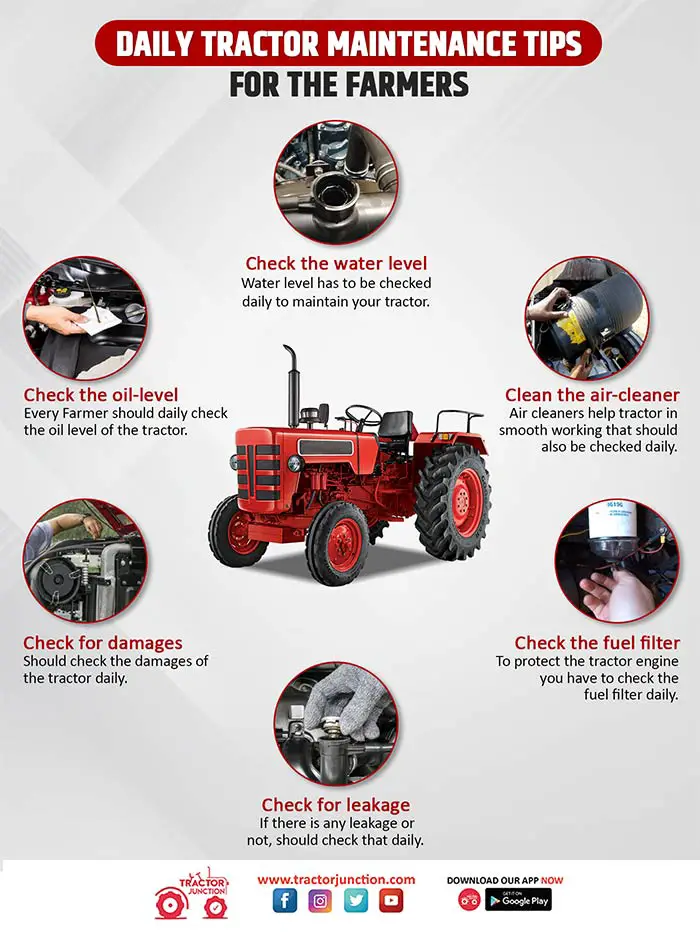

This image is property of www.tractorjunction.com.

Routine Inspection

Checking for Leaks

Performing routine inspections can help identify potential issues before they become major problems. Start by visually inspecting the engine for any signs of leaks. Look for any puddles or drips underneath the machinery, which could indicate a leak. Check all the hoses, gaskets, and seals for any signs of wear or damage. If you notice any leaks or suspect a problem, it’s essential to address it promptly to prevent further damage to the engine.

Inspecting Belts and Hoses

Another crucial aspect of routine inspection is checking the belts and hoses of your farm machinery’s engine. Over time, belts and hoses can become worn, cracked, or loose, which can affect the engine’s performance. Inspect the belts for any signs of fraying or excessive wear. Check the hoses for any cracks, bulges, or leaks. If you notice any issues, it’s important to replace the affected belts and hoses promptly to prevent engine damage.

Examining Electrical Wiring

Proper maintenance of the engine also includes examining the electrical wiring. Over time, wiring can become damaged or frayed, leading to electrical issues and potential engine problems. Inspect the wiring harness, connectors, and ignition system for any signs of damage or loose connections. If you notice any issues, it’s best to have a qualified technician inspect and repair the electrical system to ensure the engine operates smoothly and safely.

Proper Cooling System Maintenance

Checking Coolant Levels

To prevent overheating and maintain the engine’s temperature, it’s important to regularly check the coolant levels in your farm machinery. Locate the coolant reservoir, which is usually transparent and labeled. Check the coolant level against the markings on the reservoir. If the coolant level is low, add the appropriate coolant mixture as specified in the owner’s manual. Be cautious not to mix different types of coolants, as this can lead to coolant system damage.

Inspecting Radiator for Debris

The radiator plays a vital role in cooling the engine, so it’s important to keep it clean and free of debris. Regularly inspect the radiator for any signs of dirt, leaves, or other debris that may have accumulated. Use a soft brush or compressed air to gently clean the radiator fins, removing any obstructions that could restrict airflow. Be careful not to damage the fins during the cleaning process.

Flushing the Cooling System

Over time, dirt and contaminants can build up in the cooling system, compromising its efficiency. Flushing the cooling system at regular intervals helps remove these deposits and maintain optimal performance. Refer to the owner’s manual or consult a professional to determine the recommended flush interval and procedure for your farm machinery. Flushing the system typically involves draining the old coolant, flushing it with a cleaning solution, and refilling it with fresh coolant.

This image is property of www.tractorjunction.com.

Fuel System Care

Checking Fuel Filters

Proper maintenance of the fuel system is crucial for the engine’s performance. Regularly check the fuel filters for any signs of clogging or damage. The fuel filters help remove impurities and contaminants from the fuel, ensuring clean fuel reaches the engine. If the filters are dirty or clogged, they should be cleaned or replaced according to the manufacturer’s recommendations.

Draining the Fuel Tank

Performing regular fuel tank maintenance can help prevent fuel contamination and keep the engine running smoothly. Drain the fuel tank periodically to remove any water, sediment, or old fuel that may have accumulated. Follow the manufacturer’s instructions to safely drain the fuel tank and dispose of the old fuel properly.

Running Fuel Additives

Using fuel additives can help improve fuel quality, enhance engine performance, and prevent fuel system issues. Consider adding fuel additives recommended by the manufacturer or a qualified professional to your farm machinery’s fuel system. These additives can help clean the fuel injectors, improve fuel combustion, and prevent the buildup of deposits in the fuel system.

Air Filter Maintenance

Inspecting and Cleaning the Air Filter

The air filter plays a critical role in preventing dirt and debris from entering the engine. Regularly inspect the air filter for any signs of dirt, dust, or damage. If the air filter is dirty, gently tap it to remove loose debris or use compressed air to blow away the dirt. Avoid using water or harsh chemicals to clean the air filter, as this can damage it. If the air filter is beyond cleaning, it’s best to replace it with a new one to ensure optimal engine performance.

Replacing the Air Filter

If cleaning the air filter is no longer effective, it’s important to replace it with a new one. Follow the manufacturer’s instructions to ensure the proper installation of the new air filter. Properly sealing the air filter housing and ensuring a tight fit is crucial to prevent unfiltered air from entering the engine.

This image is property of www.tractorjunction.com.

Lubrication

Checking and Adding Lubricants

Lubricating the engine’s moving parts is essential to reduce friction and prevent wear and tear. Regularly check the lubricant levels, such as engine oil and grease, and add more as needed. Use the recommended lubricants specified in the owner’s manual to ensure compatibility and optimal performance. Follow the manufacturer’s instructions on how to properly add lubricants to the various components.

Greasing Bearings and Moving Parts

Properly greasing bearings and other moving parts helps ensure smooth operation and prolongs the lifespan of the engine. Regularly inspect the bearings and other components that require lubrication. Use a grease gun to apply the appropriate grease to the designated points. Be sure to use the correct type and amount of grease as recommended by the manufacturer.

Battery Care

Cleaning the Battery Terminals

The battery is a crucial component of the engine’s electrical system, so it’s important to properly maintain it. Regularly check the battery terminals for any signs of corrosion or buildup. If you notice corrosion, disconnect the battery cables and clean the terminals using a mixture of baking soda and water. Gently scrub the terminals with a wire brush to remove any corrosion. Rinse with clean water and dry the terminals thoroughly before reconnecting the battery cables.

Checking Battery Fluid Levels

To maintain the battery’s performance, it’s important to check the fluid levels regularly, especially for traditional lead-acid batteries. Most batteries have a translucent casing that allows you to see the electrolyte level. If the fluid level is low, carefully add distilled water to bring it to the recommended level. Be cautious not to overfill, as this can lead to battery damage. If your machinery has a maintenance-free battery, there is no need to check or add fluid levels.

Testing the Battery’s Charge

Regularly testing the battery’s charge helps ensure it has enough power to start the engine. Use a battery tester or a multimeter to check the voltage of the battery. If the voltage is below the recommended level, it may be time to recharge or replace the battery. Consult the owner’s manual or a professional technician for guidance on proper battery testing and maintenance.

This image is property of d3qz1qhhp9wxfa.cloudfront.net.

Thorough Inspection of Ignition System

Inspecting Spark Plugs

The spark plugs play a vital role in the engine’s combustion process, so it’s important to regularly inspect them. Remove the spark plugs and visually inspect them for any signs of wear, damage, or fouling. If the spark plugs are dirty or worn out, it’s best to replace them with new ones to ensure optimal engine performance.

Checking Ignition Timing

Proper ignition timing is crucial for the engine’s efficiency and performance. Regularly check and adjust the ignition timing according to the manufacturer’s specifications. This can typically be done using a timing light and following the specific instructions in the owner’s manual. Proper ignition timing helps ensure efficient fuel combustion and prevents engine issues.

Examining Distributor Cap and Rotor

The distributor cap and rotor are key components of the ignition system, so it’s important to inspect them regularly. Remove the distributor cap and rotor and inspect them for any signs of wear, corrosion, or damage. If you notice any issues, it’s best to replace them to ensure reliable ignition and prevent potential engine misfires.

Maintaining the Exhaust System

Inspecting for Leaks and Rust

Regularly inspecting the exhaust system is crucial for engine maintenance. Look for any signs of leaks, such as soot or black marks around the connections and joints. Inspect the exhaust pipes and muffler for any visible rust or corrosion. If you notice any leaks or excessive rusting, it’s important to repair or replace the affected components to prevent hazardous fumes from entering the cabin and to ensure optimal engine performance.

Cleaning or Replacing Muffler

The muffler helps reduce exhaust noise and directs exhaust gases out of the engine. Over time, the muffler can become clogged with dirt, debris, or rust, affecting its performance. Clean the muffler regularly using a wire brush or a muffler cleaner specifically designed for this purpose. If the muffler is heavily corroded or damaged, it may be necessary to replace it with a new one for proper engine operation.

Examining Catalytic Converter

The catalytic converter plays a crucial role in reducing harmful emissions from the engine. Regularly inspect the catalytic converter for any signs of damage or clogging. If you notice any issues, it’s important to have a qualified technician examine and repair the catalytic converter to ensure it continues to function effectively.

Proper engine maintenance plays a vital role in the longevity and performance of your farm machinery. By following these comprehensive steps for regular cleaning, oil changes, routine inspections, cooling system maintenance, fuel system care, air filter maintenance, lubrication, battery care, ignition system inspection, and exhaust system maintenance, you can ensure that your farm machinery’s engine operates smoothly and efficiently. Remember to refer to the owner’s manual for specific guidelines and consult a qualified technician when necessary. With proper maintenance, your farm machinery will continue to serve you reliably for years to come.

This image is property of www.tractorjunction.com.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.