This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

Maintaining the fuel system of your farm machinery is crucial for ensuring optimal performance and longevity. In this article, we will explore the essential steps to properly maintaining your farm machinery’s fuel system. From regular inspections and cleanings to using high-quality fuel additives, these tried and tested methods will help you keep your equipment running smoothly and efficiently, saving you time and money in the long run. Whether you’re a seasoned farmer or new to the world of agriculture, these simple tips will help you keep your farm machinery in top-notch condition. So let’s get started and give your equipment the care it deserves!

Regular Inspections

Regular inspections of the fuel system are an essential part of maintaining the efficiency and performance of your farm machinery. By conducting these inspections, you can identify any potential issues early on and take the necessary steps to prevent costly repairs or breakdowns. There are several key areas to focus on when inspecting your fuel system: checking for fuel leaks, inspecting fuel filters, and examining fuel tanks.

Checking for Fuel Leaks

One of the first things you should do during a fuel system inspection is to check for any signs of fuel leaks. Leaking fuel can not only be a fire hazard but can also lead to fuel wastage and decreased efficiency. Start by visually inspecting all the fuel lines and connections for any signs of leakage, such as stains or wet spots. Additionally, you can use a fuel leak detection kit, which typically consists of a fluorescent dye, to identify any small leaks that might not be visible to the naked eye. If you do find a leak, it is important to promptly repair or replace the affected component to ensure the safe operation of your machinery.

Inspecting Fuel Filters

Fuel filters play a crucial role in maintaining the cleanliness of your fuel system by trapping dirt, debris, and other contaminants before they can reach the engine. Regularly inspecting and cleaning or replacing these filters is vital to ensure proper fuel flow and prevent engine damage. Start by locating the fuel filters, which are typically found along the fuel lines or inside the fuel tank. Check for any signs of clogging or excessive dirt accumulation. If the filter appears dirty or clogged, clean it according to the manufacturer’s instructions or replace it with a new one. It is recommended to follow the manufacturer’s recommended filter replacement schedule to maintain optimal performance.

Examining Fuel Tanks

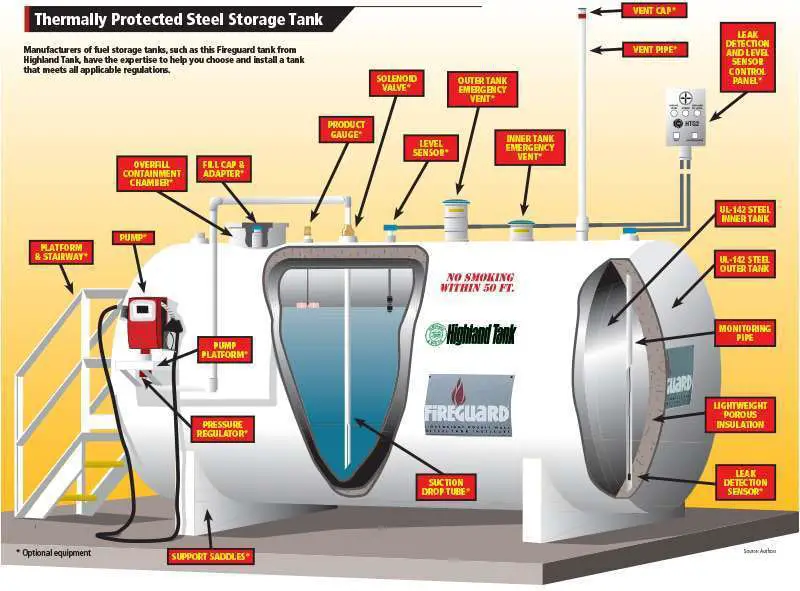

Fuel tanks should be examined regularly to ensure their integrity and prevent any potential issues that could arise from corrosion or damage. Start by inspecting the exterior of the fuel tank for any signs of leaks, rust, or physical damage. If any issues are detected, consult with a professional for further assistance. Additionally, it is crucial to check the fuel tank’s vents and ensure they are not obstructed or clogged, as proper ventilation is necessary for the fuel system to function correctly. By regularly examining your fuel tanks, you can address any potential problems early on and avoid prolonged machinery downtime.

Fuel Quality Management

Managing the quality of the fuel used in your farm machinery is essential for optimal performance and longevity of the fuel system. By investing in clean and filtered fuel and regularly draining water from the system, you can ensure the smooth operation of your machinery and minimize fuel-related issues.

Using Clean and Filtered Fuel

Using clean and filtered fuel is crucial to prevent contaminants from entering your fuel system and causing damage. Dirt, water, and other impurities can lead to clogged fuel lines, fuel injector issues, and overall reduced engine performance. Therefore, it is important to source high-quality fuel from reputable suppliers. Consider using fuel filters with a high micron rating, as they can effectively trap smaller particles and impurities. It is also recommended to have additional fuel filters installed in-line with your machinery’s fuel system to provide an extra layer of protection.

Draining Water from the Fuel System

Water contamination is a common issue in fuel systems and can lead to engine stalling, corrosion, and microbial growth. Regularly draining water from the fuel system is essential for maintaining its integrity. Most modern farm machinery is equipped with water separators or fuel system bleeder valves that allow for easy removal of accumulated water. Follow the manufacturer’s instructions to safely drain the water, and do it in a well-ventilated area as water removal can release harmful fumes. Additionally, consider using fuel additives specifically designed to prevent water accumulation and microbial growth in the fuel tank.

This image is property of www.tractorjunction.com.

Fuel Additives

Fuel additives can enhance the performance and lifespan of your fuel system by providing additional protection and addressing specific issues. Two common types of fuel additives that can benefit your farm machinery are fuel stabilizers and fuel biocides.

Using Fuel Stabilizers

Fuel stabilizers are additives designed to prevent fuel degradation and oxidation, which can occur over time. When fuel is stored for extended periods, it can deteriorate and form varnish or gum deposits that can clog fuel lines and injectors. By adding a fuel stabilizer to your storage tanks or directly to the fuel, you can prolong the shelf life of your fuel and prevent engine problems associated with degraded fuel. Follow the manufacturer’s instructions for proper dosage and usage.

Adding Fuel Biocides

Microbial growth in fuel tanks is a significant issue that can lead to clogged filters, fuel line blockages, and injector malfunctions. Fuel biocides can effectively prevent microbial infestation by eliminating bacteria, fungi, and other microorganisms that thrive in the fuel. Regularly adding a fuel biocide to your storage tanks can help keep your fuel system free from harmful contaminants. However, it is important to follow the manufacturer’s instructions and recommendations for proper dosage and application.

Fuel Storage

Proper fuel storage is crucial for maintaining the quality and performance of your fuel, as well as ensuring the safety of your machinery and farm operations. By adhering to specific storage practices and using suitable fuel containers, you can prevent fuel degradation, contamination, and potential hazards.

Proper Storage Containers

When storing fuel, it is important to use appropriate fuel storage containers that are designed for the purpose. Fuel containers should be made of durable materials that are resistant to corrosion and leakage. Metal or approved plastic containers specifically designed for fuel storage are recommended. Ensure that the containers are properly sealed to prevent the entry of water or air. Additionally, label the containers clearly with the type of fuel and the date of storage to keep track of its age and usage. Properly storing your fuel in suitable containers will help maintain its quality and prevent any potential safety hazards.

Fuel Tank Ventilation

Proper ventilation of fuel tanks is essential for maintaining the integrity of the fuel system and preventing the buildup of harmful fumes. Fuel tanks should be equipped with vents that allow air to circulate and prevent pressure or vacuum buildup. Ensure that the vents are not obstructed or clogged by dirt or debris. Regularly inspect and clean the vents to ensure their proper functioning. Adequate ventilation will help prevent fuel system issues and ensure the safe operation of your machinery.

This image is property of img.equipmentworld.com.

Fuel System Cleaning

Regularly cleaning the fuel system of your farm machinery is important to remove accumulated deposits, improve fuel flow, and maintain optimal performance. There are two main areas to focus on when cleaning the fuel system: flushing the fuel lines and cleaning fuel injectors.

Flushing the Fuel Lines

Over time, fuel lines can accumulate debris, varnish, and other deposits that can impede the flow of fuel and affect engine performance. Flushing the fuel lines helps to remove these accumulated contaminants and restore proper fuel flow. To flush the lines, start by disconnecting the fuel lines from the machinery and using a suitable cleaning solvent. Follow the manufacturer’s instructions on the solvent usage and ensure proper disposal of the solvent after use. Flush the fuel lines thoroughly with the solvent, removing any obstructions or deposits. Once the lines are cleaned, reinstall them, ensuring proper connections and secure fittings.

Cleaning Fuel Injectors

Fuel injectors play a crucial role in delivering the right amount of fuel to the engine for combustion. Over time, they can become clogged or dirty, leading to poor fuel atomization and reduced engine performance. Cleaning fuel injectors regularly is essential to maintain proper fuel spray patterns and efficient combustion. There are various methods available for cleaning fuel injectors, such as using specialized cleaning kits or professional cleaning services. Follow the manufacturer’s recommendations or consult with a professional for the best method to clean your specific fuel injectors.

Fuel Consumption Tracking

Monitoring fuel usage and maintaining accurate records can provide valuable insights into the efficiency of your farm machinery and help identify any potential issues that may be affecting fuel consumption. By tracking fuel consumption and analyzing patterns, you can make informed decisions regarding maintenance, operating practices, and potential improvements.

Monitoring Fuel Usage

Keep a log of the fuel consumption for each piece of farm machinery to track its performance and identify any significant changes or variations in fuel usage. Record the amount of fuel filled, date, distance traveled, and any operational conditions that may have influenced fuel consumption. Regularly compare fuel consumption patterns to detect any unusual or unexpected trends. Any significant deviations from normal fuel consumption should be investigated further to identify potential issues that may require attention.

Identifying Fuel Efficiency Issues

Tracking and analyzing fuel consumption records can help identify fuel efficiency issues that may be impacting the performance and profitability of your farm machinery. Unexplained increases in fuel consumption could indicate problems with the fuel system, engine, or other components. By addressing these issues promptly, you can optimize fuel efficiency and minimize operating costs. Regular fuel consumption tracking is a valuable tool for managing fuel expenses and ensuring the optimal performance of your machinery.

This image is property of www.tractorjunction.com.

Regular Maintenance

Regular maintenance of your farm machinery’s fuel system is crucial for its longevity and efficient operation. Two key maintenance practices to focus on are changing fuel filters and replacing fuel line fittings.

Changing Fuel Filters

Fuel filters should be regularly replaced to maintain the cleanliness of the fuel system and prevent engine damage. Follow the manufacturer’s recommended filter replacement schedule and ensure the use of high-quality filters. Start by locating the fuel filter(s) in your machinery’s fuel system. Using the appropriate tools and following safety guidelines, remove the old filter and replace it with a new one. Ensure proper connections and secure fittings. Regularly changing fuel filters will help prevent clogging, improve fuel flow, and safeguard the overall performance of your machinery.

Replacing Fuel Line Fittings

Fuel line fittings are susceptible to wear, corrosion, and leakage over time. Regularly inspecting and replacing these fittings is important to prevent fuel leaks and ensure the integrity of the fuel system. If any fittings show signs of damage, such as cracks or excessive corrosion, they should be promptly replaced. It is recommended to use high-quality fittings that are compatible with your machinery’s fuel system. Follow the manufacturer’s instructions and safety guidelines when replacing fuel line fittings to ensure proper installation and prevent any potential issues.

Fuel System Troubleshooting

Despite regular maintenance and inspections, fuel system problems may still arise. Understanding how to diagnose potential issues and when to seek professional help is crucial for timely resolution and preventing further damage to your farm machinery.

Diagnosing Fuel System Problems

When encountering fuel system issues, it is important to diagnose the problem accurately to determine the appropriate course of action. Common fuel system problems include fuel leaks, clogged filters, injector malfunctions, and fuel pump failures. If you notice a decrease in performance, difficulty starting your machinery, or any abnormal sounds or smells, it may indicate a fuel system problem. Consult the manufacturer’s manual or seek professional advice to help diagnose the issue. Consider checking for any error codes or warning lights on your machinery’s diagnostic system, if available.

Seeking Professional Help

If you are unable to diagnose or resolve the fuel system problem on your own, it is advisable to seek professional help. Certified technicians or mechanics with experience in fuel system repairs will have the expertise and tools necessary to identify and rectify the issue. Attempting to fix complex fuel system problems without the proper knowledge or equipment can lead to further damage or safety hazards. Professional assistance is particularly important for intricate fuel system components, such as injectors or fuel pumps, which require specialized skills and tools for repair or replacement.

This image is property of img.totallandscapecare.com.

Safety Precautions

When working with the fuel system of your farm machinery, it is vital to prioritize safety to protect yourself, your machinery, and the surrounding environment. Adhering to specific safety precautions will help minimize the risk of accidents, fires, or other potential hazards.

Working in Well-Ventilated Areas

Fuel-related work should be conducted in well-ventilated areas to prevent the accumulation of harmful fumes or vapors. Ideally, perform fuel system maintenance or repairs outside or in open spaces with proper air circulation. If working indoors, ensure that the area is properly ventilated, with windows or doors open to allow fresh air to enter. Avoid confined spaces or areas with inadequate ventilation to prevent the buildup of fuel vapors, which can be highly flammable. It is also advisable to wear appropriate personal protective equipment, such as gloves and goggles, to minimize the risks associated with fuel handling.

Avoiding Open Flames or Sparks

Open flames or sparks near a fuel system can have catastrophic consequences. Always keep ignition sources, such as open flames, cigarettes, or sparks from electrical tools, away from the fuel and fuel storage areas. Perform fuel-related work in designated areas free from potential ignition sources. Ensure that all equipment and tools used are properly grounded, and avoid any activities that may create sparks or arcs near the fuel system. By eliminating or minimizing potential ignition sources, you significantly reduce the risk of fire and explosions.

Stay Informed

Keeping yourself informed about the specific requirements and recommendations for your farm machinery’s fuel system is essential for proper maintenance and safe operation. Consult the manufacturer’s manual and attend training programs to stay up to date with the latest guidelines and best practices.

Consulting Manufacturer’s Manual

The manufacturer’s manual is an invaluable resource that provides essential information regarding fuel system maintenance, troubleshooting, and safety guidelines for your specific farm machinery. Familiarize yourself with the manual and refer to it regularly for any questions or concerns. The manual will outline the recommended maintenance schedules, filter replacement intervals, and any specific fuel additives or treatments that are compatible with your machinery. By consulting the manufacturer’s manual, you can ensure that you are following the correct procedures and using appropriate products for your fuel system maintenance.

Attending Training Programs

Attending training programs or workshops related to fuel system maintenance and operation can provide you with valuable knowledge and skills to effectively manage your farm machinery. These programs are often organized by manufacturers, industry associations, or professional training institutes. During these sessions, you can learn about the latest advancements in fuel system technology, best practices for maintenance, and the proper use of fuel additives and treatments. By participating in training programs, you can stay informed about industry trends, enhance your understanding of fuel system management, and ultimately optimize the performance of your farm machinery.

In conclusion, proper maintenance of the fuel system in your farm machinery is crucial for optimal performance, longevity, and safety. Regular inspections, fuel quality management, the use of fuel additives, appropriate fuel storage practices, fuel system cleaning, fuel consumption tracking, and regular maintenance are all important aspects to consider. By following these comprehensive guidelines and adhering to safety precautions, you can ensure the smooth operation of your farm machinery and maximize its efficiency, ultimately contributing to the success of your farm operations. Stay informed by consulting the manufacturer’s manual and attending training programs to stay up to date with the latest practices and recommendations for fuel system maintenance.

This image is property of cdn.equipmentradar.com.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.