This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

Maintaining the transmission of your farm machinery is crucial to ensure its optimal performance and longevity. From tractors to harvesters, the transmission plays a vital role in helping these machines operate smoothly and efficiently. In this article, you will discover some helpful tips and techniques on how to properly maintain the transmission of your farm machinery. Whether you are a seasoned farmer or just starting out, taking care of your transmission will not only save you time and money but also keep your farm operations running smoothly. So let’s dig in and explore the best practices for maintaining your farm machinery’s transmission.

This image is property of www.robustec.ind.br.

1. Regular Inspection

Regularly inspecting the transmission of your farm machinery is crucial for its overall performance and longevity. By conducting routine checks, you can identify any potential issues early on and take necessary actions to prevent costly repairs down the line. Here are some key aspects to focus on during your regular inspection:

1.1 Check Fluid Levels

First and foremost, it is essential to regularly check the fluid levels in your transmission. Low fluid levels can result in inefficient performance and increased wear and tear on the system. Consult your machinery’s manual to determine the appropriate fluid level for your specific model. Make sure to check the levels when the machinery is cool, and the engine is turned off.

1.2 Inspect for Leaks

Another critical aspect of regular inspection is checking for any leaks in the transmission system. Leaks can lead to a decrease in fluid levels and compromise the overall performance of your machinery. Inspect the transmission for any signs of fluid leakage, such as puddles or oil stains on the ground, and address any leaks promptly to prevent further damage.

1.3 Check Clutch

The clutch is an integral part of the transmission system that allows you to change gears smoothly. During your regular inspection, pay close attention to the clutch’s condition, ensuring that there are no signs of excessive wear or damage. If you notice any abnormalities, such as slipping or difficulty shifting gears, it may be necessary to have the clutch inspected and potentially replaced by a professional.

1.4 Monitor Transmission Temperature

Monitoring the temperature of your machinery’s transmission is essential to prevent overheating, which can cause significant damage. Keep an eye on the transmission temperature gauge or use a thermometer if your machinery doesn’t have a built-in gauge. If the temperature rises above the recommended range, take immediate action by allowing the machinery to cool down and investigating the cause, such as a malfunctioning cooling system or excessive workload.

2. Fluid Maintenance

Proper fluid maintenance is vital for optimal transmission performance and longevity. The transmission fluid acts as a lubricant, cooling agent, and hydraulic fluid, ensuring smooth operation of the gears and components within the transmission. Here are some key points to consider regarding fluid maintenance:

2.1 Use the Recommended Fluid

Using the right type of transmission fluid is crucial for maintaining the integrity of your farm machinery’s transmission. Refer to the machinery’s manual or consult with a professional to determine the recommended fluid type for your specific model. Different machinery may require different types of fluids, such as automatic transmission fluid (ATF) or hydraulic fluid. Using the wrong fluid can lead to poor performance and potential damage.

2.2 Change Fluid Regularly

Regularly changing the transmission fluid is essential to remove any contaminants or debris that may accumulate over time. The frequency of fluid changes will depend on your machinery’s usage and operating conditions. Consult the machinery’s manual for specific recommendations on the interval at which the transmission fluid should be changed. Generally, it is advisable to change the fluid every few thousand operating hours or as recommended by the manufacturer.

2.3 Inspect for Contamination

Aside from regular fluid changes, it is important to inspect the transmission fluid for any signs of contamination during routine maintenance. Contaminated fluid can cause damage to internal components and hinder the transmission’s performance. Check for any unusual coloration, particles, or a burnt smell in the fluid. If you notice any of these signs, it is crucial to address the issue promptly by changing the fluid and investigating the cause of the contamination.

3. Filter Replacement

Filters play a vital role in preventing contaminants from entering the transmission system. Over time, these filters can become clogged or worn out, reducing their effectiveness. Regularly replacing the filters ensures optimal filtration and helps maintain the transmission’s performance. Here are two key filters that require attention:

3.1 Replace Fluid Filter

The fluid filter is responsible for removing debris and contaminants from the transmission fluid. It is important to regularly replace the fluid filter as recommended by the manufacturer or during routine fluid changes. Failing to replace a clogged or damaged filter can lead to decreased fluid flow and increased wear on the transmission components.

3.2 Replace Air Filter

In addition to the fluid filter, the air filter also plays a crucial role in maintaining the transmission’s efficiency. The air filter prevents dust, debris, and other airborne particles from entering the transmission. Inspect the air filter regularly and replace it if it appears dirty or clogged. A clean air filter ensures proper airflow and prevents contaminants from entering and damaging the transmission system.

4. Proper Lubrication

Proper lubrication is essential for reducing friction and prolonging the lifespan of various transmission components. Here are some key areas that require lubrication:

4.1 Grease the Bearings

Bearings are essential components of the transmission system that provide smooth rotation and reduce friction. Regularly greasing the bearings will help prevent premature wear and ensure smooth operation. Consult the machinery’s manual for the recommended lubrication schedule and use high-quality grease suitable for your specific bearings.

4.2 Lubricate the PTO Shaft

The Power Take-Off (PTO) shaft transfers mechanical power from the machinery’s engine to the attached implements. Lubricating the PTO shaft regularly is crucial to reduce friction and prevent corrosion. Follow the manufacturer’s recommendations for the appropriate lubricant and interval for PTO shaft lubrication.

4.3 Apply Grease to Input Shaft Splines

The input shaft splines play a vital role in transmitting power from the engine to the transmission. It is important to apply a suitable grease to the input shaft splines regularly to prevent corrosion and ensure smooth power transfer. Refer to the machinery’s manual for specific instructions on the type of grease to use and the recommended lubrication frequency.

This image is property of blog.machinefinder.com.

5. Cleaning and Debris Removal

Regularly cleaning your farm machinery’s transmission helps prevent the accumulation of dirt, debris, and other contaminants that can negatively impact its performance. Here are some key areas to focus on when cleaning:

5.1 Remove Dirt and Debris

Start by thoroughly removing any visible dirt and debris from the transmission and its surrounding areas. Use a soft brush or compressed air to dislodge dirt from hard-to-reach areas. Pay special attention to areas where dirt tends to accumulate, such as around seals and joints.

5.2 Clean Cooling Fins

The cooling fins on the transmission are responsible for dissipating heat and maintaining optimal operating temperatures. Over time, these fins can accumulate dirt and debris, reducing their effectiveness. Regularly clean the cooling fins using a soft brush or compressed air to ensure proper heat dissipation and prevent overheating.

5.3 Clean Radiator and Oil Cooler

The radiator and oil cooler are integral parts of the cooling system that help regulate the transmission’s temperature. It is important to keep these components clean to prevent overheating. Gently clean the radiator and oil cooler using a soft brush or compressed air, removing any dirt, leaves, or debris that may have accumulated on the surfaces.

6. Cooling System

The cooling system plays a significant role in preventing overheating and maintaining optimal operating temperatures for your farm machinery’s transmission. Regular maintenance of the cooling system helps ensure efficient heat dissipation. Here are some key aspects of cooling system maintenance:

6.1 Check Coolant Levels

Regularly check the coolant levels in the radiator and ensure they are within the recommended range. Low coolant levels can lead to inadequate cooling and potential overheating. If necessary, add the appropriate coolant type as specified by the manufacturer to maintain optimal coolant levels.

6.2 Inspect Hoses and Belts

Inspect the cooling system hoses and belts for signs of wear, cracks, or leaks. Damaged hoses or belts can result in coolant leaks, reduced cooling efficiency, and potential transmission overheating. Replace any damaged or worn-out hoses and belts promptly to prevent further issues.

6.3 Flush the Cooling System

Over time, the cooling system can accumulate contaminants, rust, and scale, hindering its efficiency. Periodically flushing the cooling system helps remove these deposits and ensures proper coolant flow. Refer to the machinery’s manual for specific instructions on how to flush the cooling system and the recommended interval for this procedure.

This image is property of www.pequea.com.

7. Transmission Fluid Cooling

In addition to the machinery’s internal cooling system, an external transmission cooler can help maintain optimal transmission temperatures. Consider these aspects of transmission fluid cooling:

7.1 Install Transmission Cooler

If your farm machinery frequently operates under heavy loads or in high-temperature environments, installing an additional transmission cooler may be beneficial. A transmission cooler helps dissipate heat more effectively, reducing the risk of overheating and prolonging the transmission’s lifespan. Consult with a professional to determine the appropriate transmission cooler for your specific machinery.

7.2 Monitor Cooling Performance

Once you have installed an additional transmission cooler, it is important to monitor its cooling performance regularly. Keep an eye on the transmission temperature and ensure that it remains within the recommended range, even under demanding conditions. If you notice any signs of overheating, such as excessive temperature spikes, it may be necessary to reevaluate the cooling system setup or seek expert advice.

8. Proper Use and Operation

Properly using and operating your farm machinery is essential for the well-being of its transmission system. Here are some key points to consider for optimal use and operation:

8.1 Avoid Overloading

Overloading your machinery can put excessive strain on the transmission, leading to premature wear and potential breakdowns. Refer to the machinery’s manual for the recommended load capacity and avoid exceeding this limit. Distribute loads evenly and refrain from abruptly changing gears while under heavy load to minimize stress on the transmission.

8.2 Follow Recommended Procedures

Always follow the recommended procedures outlined in the machinery’s manual for starting, operating, and shutting down your equipment. Ignoring these procedures or taking shortcuts can lead to unnecessary strain on the transmission and other components. Properly engaging the clutch, shifting gears smoothly, and using the appropriate operating techniques will help preserve the transmission’s integrity.

8.3 Maintain Proper Speeds

Maintaining proper speeds while operating your farm machinery is crucial for the transmission’s well-being. Avoid excessive speeds that can put excessive stress on the transmission, as well as sudden accelerations or decelerations that can cause unnecessary strain. Operate your machinery at moderate speeds suitable for the terrain and conditions to ensure the transmission operates smoothly and efficiently.

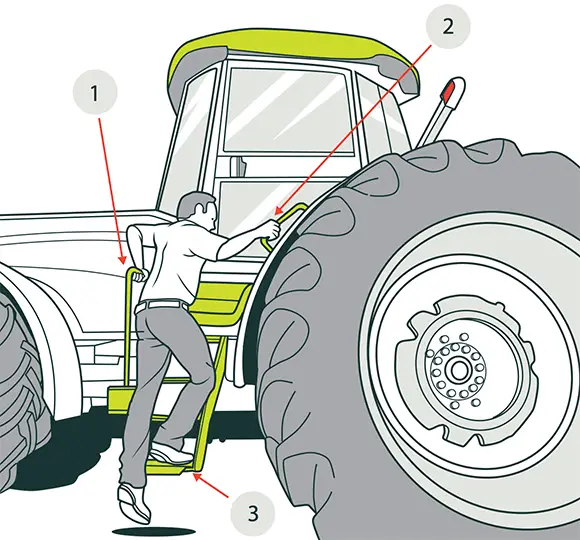

This image is property of www.worksafe.govt.nz.

9. Storage and Winterization

Proper storage and winterization practices are essential for maintaining your farm machinery’s transmission during periods of non-use or colder months. Implement the following measures to ensure the transmission remains in optimal condition during storage:

9.1 Use Fuel Stabilizer

Before storing your machinery, add a fuel stabilizer to the fuel tank to prevent the fuel from deteriorating and causing issues within the transmission. Fuel stabilizers help prevent the formation of varnish and gum that can clog fuel lines or damage the carburetor. Follow the manufacturer’s instructions for the appropriate amount of fuel stabilizer to use.

9.2 Store in a Dry Location

Choose a dry, well-ventilated storage location for your farm machinery to prevent moisture build-up and potential corrosion. Moisture can penetrate the transmission components and lead to rust or other damage. If feasible, consider using a specially designed storage shed or covering the machinery with a waterproof tarp.

9.3 Perform Pre-winter Maintenance

Performing pre-winter maintenance is essential for preparing your farm machinery’s transmission for the colder months. Change the transmission fluid and filter if necessary, ensuring that fresh, clean fluid is present during storage. Additionally, inspect the cooling system, belts, and hoses for any signs of wear or damage, addressing any issues before storing the machinery.

10. Professional Servicing

While regular maintenance and inspections can go a long way in maintaining your farm machinery’s transmission, it is important to seek professional servicing when necessary. Here are two key points to consider regarding professional servicing:

10.1 Schedule Routine Servicing

Make it a priority to schedule routine servicing with a qualified technician or service center. Routine servicing allows professionals to thoroughly inspect the transmission, identify potential issues, and perform necessary repairs or replacements. Regular servicing ensures that your machinery’s transmission receives the expert attention it needs for optimal performance and longevity.

10.2 Seek Expert Advice

If you encounter any persistent issues or are unsure about proper maintenance procedures, do not hesitate to seek expert advice. Experienced technicians and service professionals can provide valuable insights, troubleshooting assistance, and guidance specific to your farm machinery’s transmission. They have the expertise to diagnose and resolve complex problems while helping you avoid costly mistakes.

By following these comprehensive maintenance guidelines, you can ensure the longevity and optimal performance of your farm machinery’s transmission. Regular inspections, fluid maintenance, filter replacements, proper lubrication, cleaning, and proper use and operation will help keep your transmission running smoothly. Additionally, proper storage, winterization, and seeking professional servicing when necessary will help address specific needs and challenges that may arise. Remember, taking care of your transmission today means avoiding costly repairs and downtime in the future. Happy farming!

This image is property of www.ruralmutual.com.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.