This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

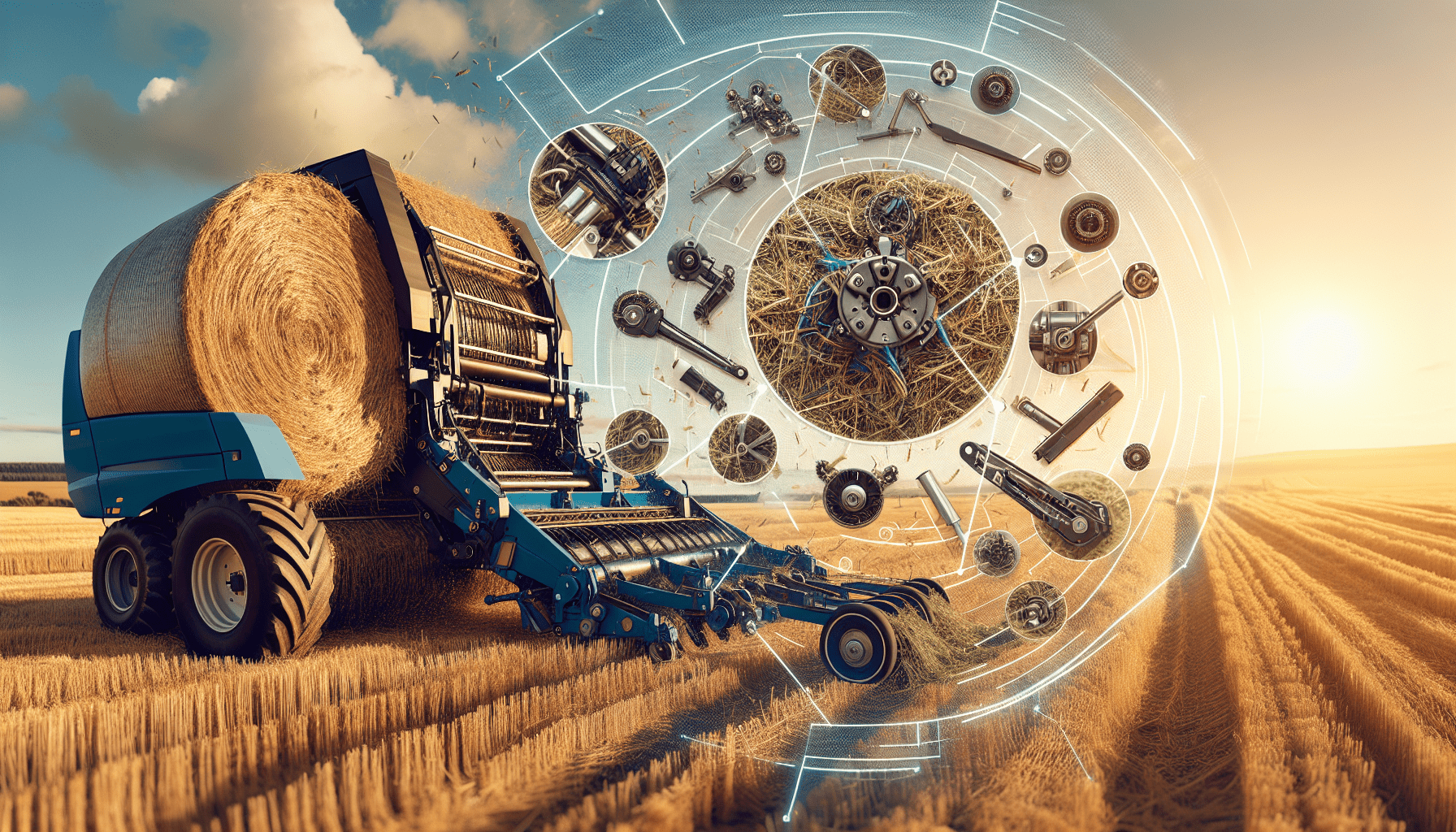

When it comes to hay balers, finding the right type for your farm is crucial for efficient and successful baling. With a wide range of options available, it’s important to consider factors such as your farm’s size, the types of crops you grow, and your desired baling method. This article will guide you through the key considerations involved in choosing the right hay baler for your farm, helping you make an informed decision that will optimize your hay baling process and yield high-quality results.

Assessing Your Hay Baling Needs

When it comes to hay baling, it’s important to assess your specific needs and requirements before investing in a hay baler. Understanding your needs will help you determine the most suitable type of hay baler for your farm. There are several factors to consider, including the purpose of the hay baler, the amount of hay produced, the frequency of baling, and the type and condition of your hay.

Understanding the Purpose of a Hay Baler

First and foremost, it’s essential to understand the purpose of a hay baler. A hay baler is a piece of agricultural equipment designed to efficiently gather, compress, and package hay into bales. The main purpose of a hay baler is to make the hay easier to store, transport, and feed to livestock. By baling your hay, you can maximize storage capacity, reduce labor costs, and ensure consistent feed quality for your animals.

Determining the Amount of Hay Produced

The amount of hay you produce plays a significant role in determining the type of hay baler you need. If you have a small farm that produces a modest amount of hay, a small square baler may be sufficient for your needs. However, if you have a larger operation that yields a substantial quantity of hay, you may need a larger square baler, a round baler, or even a self-propelled baler to handle the workload more efficiently.

Considering the Frequency of Baling

Another crucial factor to consider is the frequency of baling. How often do you plan on baling hay throughout the year? If you have a high demand for hay or multiple cuttings throughout the growing season, you may need a hay baler with a higher baling capacity. On the other hand, if you have a smaller operation and only bale hay occasionally, a hay baler with a lower capacity may be more suitable.

Analyzing the Type and Condition of Hay

The type and condition of your hay should also be taken into account when choosing a hay baler. Different types of hay, such as alfalfa, timothy, or grass, may have different characteristics and baling requirements. Additionally, the condition of your hay, whether it’s dry or moist, can impact the type of baler you should use. Some balers are better equipped to handle wet or heavy hay, while others are more suited for dry and lightweight hay.

Types of Hay Balers

Now that you have a better understanding of your hay baling needs, let’s explore the different types of hay balers available. There are several options to choose from, each with its own advantages and considerations.

Small Square Balers

Small square balers are commonly used for small to medium-sized farms that produce a moderate amount of hay. These balers are known for their compact size and simplicity of operation. They produce small, rectangular bales that are easy to handle and store. If you have limited storage space or prefer manually handling your bales, a small square baler may be the right choice for you.

Large Square Balers

Large square balers are designed for farms that produce a considerable amount of hay and require high baling capacity. These balers can produce larger, uniform square bales that are quick and efficient to handle. The larger size of the bales translates to reduced handling and transportation costs. If you have a larger operation and need to bale hay in large quantities, a large square baler may be the most suitable option.

Round Balers

Round balers are a popular choice for many farmers due to their versatility and efficiency. These balers create cylindrical bales that are tightly packed and can vary in size. Round balers are known for their ability to handle different types of hay and accommodate varying moisture levels. They are particularly useful for those dealing with wet hay conditions. If you require flexibility in bale size and compatibility with different types of hay, a round baler may be the right choice for you.

Self-Propelled Balers

If you have a large-scale operation and prioritize efficiency and convenience, a self-propelled baler may be worth considering. These balers are built into a tractor or power unit, allowing for seamless operation and increased productivity. Self-propelled balers are ideal for large farms or contractors who require a high baling capacity and want to minimize labor and equipment requirements.

Considering Your Farm Size and Layout

In addition to your hay baling needs and the type of baler, it’s important to consider your farm’s size and layout. This will help you determine the most practical and efficient baler for your specific requirements.

Assessing Available Space for Balers

Before purchasing a hay baler, assess the available space on your farm. Consider the dimensions of the baler and how it will fit within your existing infrastructure. Ensure that you have enough space to safely maneuver the baler during operation and when storing bales.

Analyzing Access Points and Maneuverability

Evaluate the access points and maneuverability on your farm. Are there narrow gateways or areas with restricted access? Ensure that the chosen hay baler can navigate your farm without complications. Additionally, evaluate the turning radius and maneuverability of the baler in confined spaces.

Considering Storage Capacity for Bales

Take into account the storage capacity available for bales on your farm. If you have limited space for storing hay, it may be necessary to consider a baler that produces smaller bales or requires less storage room. On the other hand, if you have ample storage space, you can opt for a baler that produces larger bales.

Evaluating the Number of Fields and Distance

Consider the number of fields you have and the distance between them. If you have multiple fields located far apart, it may be beneficial to invest in a baler with higher speed and capacity to optimize your time and resources. Conversely, if you have a smaller operation with fields in close proximity, a baler with lower speed and capacity may suffice.

Analyzing Power and Compatibility

When choosing a hay baler, it’s important to consider the power requirements and compatibility with other equipment on your farm. This will ensure efficient operation and prevent any compatibility issues.

Matching Hay Baler to Tractor Power

Ensure that the power output of your tractor is compatible with the hay baler you choose. The baler should match or exceed the power requirements specified by the manufacturer. Using a baler that exceeds your tractor’s power capacity can result in inefficiency, increased fuel consumption, and potential damage to the equipment.

Considering Compatibility with Other Equipment

If you have other equipment on your farm, such as loaders or trailers, ensure that the chosen hay baler is compatible with these. Consider the hitching options, hydraulic connections, and any additional attachments required for seamless and efficient operation.

Evaluating the Need for Hydraulic Power

Some hay balers require hydraulic power to operate certain functions, such as bale ejection or knotter systems. Assess whether your tractor has the necessary hydraulic connections and capacity to meet the requirements of the baler you choose. If not, you may need to consider investing in additional hydraulic systems or opt for a baler with fewer hydraulic dependencies.

Understanding Bale Size and Weight

Determining the desired size and weight of your bales is crucial when selecting a hay baler. This will depend on various factors, including handling and transportation preferences, livestock feeding requirements, and overall efficiency.

Determining Desired Bale Dimensions

Consider the dimensions that best suit your needs. Smaller bales are typically easier to handle and transport, while larger bales require less manual labor for harvesting and storage. However, larger bales may require specialized equipment for handling and feeding.

Considering Handling and Transportation

Evaluate the accessibility and logistics associated with handling and transporting the bales. If you have limited manpower or equipment for moving bales, smaller and lighter bales may be more practical. On the other hand, if you have the necessary machinery and workforce, larger bales may be a more efficient option.

Analyzing Livestock Feeding Requirements

Consider the feeding requirements of your livestock. Different animals have specific needs when it comes to the size and weight of the bales they consume. Analyze whether smaller or larger bales are more suitable for your livestock’s feeding habits and efficiency.

Evaluating Baling Efficiency

The efficiency of the baling process is a critical consideration for any farmer. Analyzing different aspects of baling efficiency will help you make an informed decision when choosing a hay baler.

Understanding Baling Speed and Capacity

The baling speed and capacity of a hay baler can significantly impact your overall efficiency. Balers with higher baling speeds and capacities can help you complete the baling process more quickly, allowing you to move on to other essential tasks on your farm. However, it’s important to balance speed with the quality of bales produced and the capacity to handle different hay types.

Analyzing Baling Process Automation

Consider the level of automation you desire in your baling process. Some balers offer advanced automation features, such as automatic twine tying or bale monitoring systems. These can streamline the operation and improve overall efficiency. However, more automation can come with a higher initial cost and require additional training for operation and maintenance.

Considering Manual vs. Automatic Options

Decide whether you prefer a manual or automatic hay baler. Manual balers provide more control and flexibility but require more manual labor. Automatic balers can significantly reduce labor requirements but may come with a higher initial cost and require more maintenance. Consider your labor capabilities, budget, and efficiency goals when making this decision.

Evaluating Maintenance and Downtime

Consider the maintenance requirements and potential downtime associated with the hay baler. Look for balers that are known for their reliability and ease of maintenance. Balers with readily available replacement parts and good manufacturer support can help minimize downtime and keep your baling operation running smoothly.

Considering Crop Diversity

If you have diverse crops on your farm, it’s important to assess the compatibility of the hay baler with different types of crops.

Assessing Compatibility with Different Crops

Some hay balers are designed to handle specific types of crops more efficiently. Consider whether the baler you’re interested in can handle the variety of crops you grow. Different crops may have different cutting and drying requirements, which can impact the baling process.

Analyzing Bale Density Adjustability

Evaluate whether the hay baler allows for the adjustment of bale density. Different crops may require varying levels of compression and density to maintain bale integrity and preserve feed quality. A baler that offers bale density adjustability can cater to different crop types and help optimize the storage and nutritional value of the bales.

Considering Harvesting Conditions and Weather

Take into account your typical harvesting conditions and weather patterns. Some balers may perform better in wet or dry conditions, depending on their design and features. If you often encounter challenging weather conditions, choose a baler that can effectively handle these conditions to ensure consistent bale quality and production.

Evaluating Versatility for Future Crop Expansion

Consider your future plans for crop expansion. If you anticipate growing different types of crops in the future, you’ll want a hay baler that can accommodate these changes. Look for balers that offer versatility and can handle a wide range of crops to ensure long-term suitability.

Budgetary Considerations

Before making any equipment purchase, it’s essential to consider your budget and the costs associated with owning and operating a hay baler.

Analyzing Initial Investment Costs

Determine the initial investment costs associated with purchasing a hay baler. Prices can vary significantly depending on the type and features of the baler. Consider your budget and weigh it against the benefits and capabilities of the different balers available.

Evaluating Long-Term Operational Costs

In addition to the initial investment, evaluate the long-term operational costs of owning a hay baler. This includes maintenance, replacement parts, fuel or energy consumption, and any additional labor requirements. Balers that require less maintenance or consume less fuel can result in long-term cost savings.

Considering Financing Options

If the upfront cost of purchasing a hay baler is a concern, explore different financing options. Many manufacturers and financial institutions offer financing programs specifically for agricultural equipment. These programs can help you spread out the cost of the baler over time and make it more financially manageable.

Seeking Advice and Expertise

When making a significant investment like purchasing a hay baler, it’s always beneficial to seek advice and expertise from experienced professionals in the agricultural industry.

Consulting Local Agricultural Experts

Reach out to local agricultural experts, such as extension agents or consultants, who can provide valuable insights and recommendations based on their knowledge and experience. They can help assess your specific needs and guide you in selecting the most suitable hay baler for your farm.

Seeking Recommendations from Fellow Farmers

Connect with fellow farmers who have first-hand experience with different hay balers. Seek their recommendations and ask for feedback on the performance, reliability, and overall satisfaction of the balers they use. Hearing from others in similar farming operations can provide valuable insights and help inform your decision.

Attending Farming Equipment Exhibitions

Consider attending farming equipment exhibitions and trade shows where you can explore different hay baler options firsthand. These events offer an opportunity to see the balers in action, speak directly with manufacturers and dealers, and gain a better understanding of the features and capabilities of different models.

Contacting Equipment Manufacturers

Reach out to hay baler manufacturers directly to gather more detailed information about their products. Manufacturers can provide specifications, answer any specific questions you may have, and help you identify the most suitable hay baler based on your unique requirements. Don’t hesitate to contact them and take advantage of their expertise.

Testing and Demo Opportunities

Before making a final decision, take advantage of testing and demo opportunities to ensure that the hay baler meets your expectations and performs well in your specific farming conditions.

Finding Opportunities for On-Farm Testing

Inquire if manufacturers or local dealers offer on-farm testing of their hay balers. This allows you to see the baler in your own fields and evaluate its performance firsthand. On-farm testing provides valuable insights into how the baler handles your specific crops, soil conditions, and terrain.

Participating in Equipment Demonstrations

Many manufacturers and dealers organize equipment demonstrations where their hay balers are showcased. Attend these demonstrations to witness the baler’s performance, ask questions, and interact with industry professionals. Demonstrations can be an excellent opportunity to compare different balers and gain confidence in your decision.

Exploring Rental Options

Consider renting a hay baler before making a purchase. Renting allows you to test different models and assess their suitability for your specific needs without the commitment of owning. This can be particularly beneficial if you’re unsure about which type of baler is most suitable or if you have a temporary increase in hay production.

Considering Second-hand Equipment

If budget is a primary concern or if you’re looking for a more cost-effective option, explore the market for second-hand hay balers. There are often used balers available for purchase at a lower price point. Before purchasing second-hand equipment, thoroughly inspect the baler, consider its maintenance history, and ensure it meets your specific requirements.

By following these steps and thoroughly considering your hay baling needs, you can confidently choose the right type of hay baler for your farm. Remember to consult experts, gather recommendations, and take advantage of testing opportunities to ensure a well-informed decision. Happy baling!

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.