This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

Ready to achieve precise planting results with your seed drill? Look no further! In this article, you’ll learn the essential techniques for calibrating and operating your seed drill to ensure accurate seed placement. Get ready to dive into the world of seed drill calibration and operation!

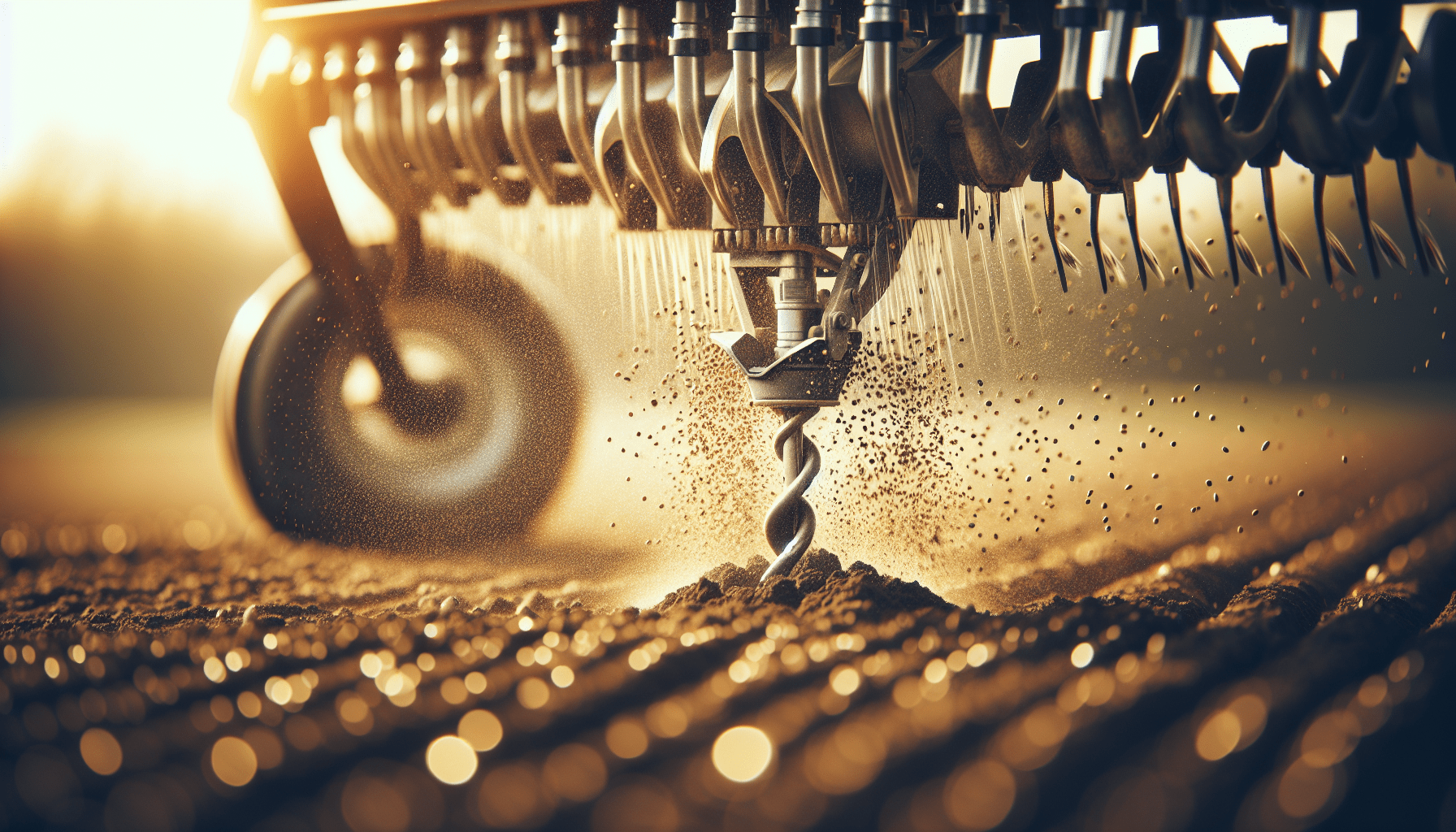

Seed Drill Overview

A seed drill is a crucial piece of equipment for farmers and agricultural workers as it allows for efficient and accurate planting of seeds. By understanding the purpose of a seed drill, knowing its components, and realizing the benefits of using one, you can maximize your productivity and ensure successful planting results.

Understanding the Purpose of a Seed Drill

The primary purpose of a seed drill is to precisely and evenly plant seeds in the soil, which promotes optimal germination and plant growth. Unlike manual planting methods, a seed drill allows for consistent seed placement, reducing wastage and ensuring even crop establishment. With a seed drill, you can save time, effort, and resources while achieving higher crop yields.

Components of a Seed Drill

A seed drill is made up of several key components that work together to facilitate the planting process. These components include the seed hopper, seed metering mechanism, seed tubes, coulters, and furrow openers. The seed hopper holds the seeds, which are then dispensed by the seed metering mechanism. The seed tubes deliver the seeds to the furrow created by the coulters and furrow openers, ensuring accurate seed placement.

Benefits of Using a Seed Drill

Using a seed drill offers numerous benefits that contribute to more efficient and successful planting. First and foremost, a seed drill ensures uniform seed spacing and depth, resulting in uniform crop emergence. This leads to better competition among plants for resources and reduces the need for extensive thinning or replanting. Additionally, a seed drill allows for faster planting speeds, minimizing planting delays and maximizing productivity. Moreover, the precise seed placement provided by a seed drill facilitates targeted fertilizer application and decreases herbicide usage, promoting sustainable and environmentally friendly farming practices.

Pre-calibration Preparations

Before using a seed drill, it is essential to conduct pre-calibration preparations to ensure optimal performance and accuracy during planting. These preparations include checking and cleaning the seed drill, inspecting and replacing worn-out parts, and greasing and lubricating moving parts.

Checking and Cleaning the Seed Drill

Start by thoroughly inspecting the seed drill for any signs of damage or wear. Check all bolts, nuts, and connections to ensure they are tight and secure. Remove any debris, such as dirt or crop residue, from the seed drill, as this can hinder proper functioning.

Inspecting and Replacing Worn-out Parts

Examine each component of the seed drill for signs of wear and tear. Look for damaged or worn-out parts, such as coulters, furrow openers, or seed meters, and replace them if necessary. Regular maintenance and timely replacement of worn-out parts are crucial to maintaining the seed drill’s accuracy and efficiency.

Greasing and Lubricating Moving Parts

Proper lubrication of moving parts is essential for smooth operation and longevity of the seed drill. Apply lubricating oil or grease to the necessary areas, such as bearings, chains, and gears, as specified in the manufacturer’s instructions. Regular greasing ensures reduced friction, decreased wear and tear, and optimized performance of the seed drill.

Calibrating the Seed Drill

Calibrating a seed drill is a critical step to ensure accurate seeding rates and proper seed placement. By following these steps, you can calibrate your seed drill effectively and achieve optimal planting results.

Selecting the Appropriate Seed Type and Size

Different crops require different seed types and sizes, so it is essential to select the appropriate seed for your intended crop. Consult seed catalogs or experts to determine the ideal seed type and size for your specific needs.

Determining the Desired Seeding Rate

The seeding rate refers to the number of seeds to be planted per unit area. The desired seeding rate varies depending on the crop, soil conditions, and farming goals. Consult planting guides, agricultural experts, or local agricultural extension services to determine the ideal seeding rate for your specific situation.

Setting the Seed Drill’s Adjustments for Calibration

Refer to the seed drill’s instruction manual to locate the calibration adjustments. These adjustments allow you to modify seed spacing, depth, and population to achieve accurate and consistent seed placement. Follow the manufacturer’s recommended settings for your selected seed type and desired seeding rate.

Running Test Runs to Verify Accuracy

Once the seed drill is calibrated, it is crucial to run a few test runs to ensure its accuracy. Plant seeds in a controlled area and observe the seed placement, spacing, and depth. If any inconsistencies or irregularities are detected, readjust the calibration settings until the desired accuracy is achieved.

Operational Guidelines

Proper operation of a seed drill plays a significant role in achieving accurate and successful planting results. Adhering to these operational guidelines will help you maximize the seed drill’s efficiency and ensure optimal crop establishment.

Proper Tractor Speed for Even Seed Distribution

Maintaining an appropriate tractor speed is vital to ensure even seed distribution. Excessive speed can result in uneven spacing and inadequate seed-to-soil contact, while slow speed may lead to overpopulation and seed wastage. Consult the seed drill’s manufacturer guidelines for the recommended tractor speed for your specific seed drill model.

Ensuring Correct Depth and Spacing

Seed depth and spacing are critical factors in crop establishment and yield potential. Adjust the seed drill’s settings to achieve the desired seed depth and spacing. Monitoring these factors during operation and making necessary adjustments will help ensure uniform crop emergence and minimize competition among plants.

Accounting for Field and Soil Conditions

Field and soil conditions may vary across different areas of your farm, so it is essential to account for these variations during seed drill operation. Adjust the seed drill settings to accommodate changes in soil type, moisture content, and terrain. Regularly monitor the field conditions to ensure proper seed placement and adjust the seed drill settings as necessary.

Avoiding Overfilling or Underfilling the Seed Drill

Properly filling the seed hopper is crucial for accurate seed placement and continuous operation. Overfilling the seed drill may lead to seed spillage, uneven distribution, and potential equipment damage. On the other hand, underfilling the seed drill can result in interrupted operation and reduced efficiency. Follow the seed drill’s capacity guidelines and fill the hopper appropriately to ensure smooth and consistent planting.

Best Practices for Seed Drill Operation

To maximize the performance and longevity of a seed drill, it is essential to follow best practices during its operation. By adhering to the manufacturer’s instructions, monitoring and adjusting as needed, and conducting proper cleaning and maintenance after use, you can optimize the seed drill’s efficiency and ensure accurate planting results.

Following Manufacturer’s Instructions

Every seed drill may have specific operational guidelines provided by the manufacturer. It is crucial to familiarize yourself with these instructions and follow them diligently. Pay attention to any specific recommendations or precautions to ensure safe and efficient operation.

Monitoring and Adjusting as Needed

Continuous monitoring of the seed drill’s performance during operation is essential to identify any irregularities or issues promptly. Keep an eye on seed placement, depth, and spacing and make necessary adjustments if discrepancies are noticed. Regularly inspect the seed drill’s components for signs of wear or damage and replace them as required.

Cleaning and Maintenance After Use

Proper cleaning and maintenance after each use are essential to prolong the seed drill’s lifespan and ensure its optimal performance in future planting seasons. Thoroughly clean the seed drill, removing any debris or residue that may hinder its operation. Inspect and lubricate moving parts, tighten bolts and nuts, and store the seed drill in a dry and secure place.

Troubleshooting Seed Drill Issues

Despite proper calibration and operation, seed drill issues may sometimes arise. By being aware of common problems and their potential solutions, you can address these issues promptly and minimize their impact on planting success.

Uneven Seed Distribution

If you notice uneven seed distribution during planting, the seed drill’s calibration may need adjustment. Check the seed metering mechanism and ensure it is working correctly. Additionally, confirm that the seed tubes and coulters are clear of any obstructions or blockages that could impede proper seed delivery.

Seeds Getting Stuck or Blocked

If seeds get stuck or blocked in the seed drill, carefully inspect the seed tubes, coulters, and furrow openers for any clogs. Remove any debris or obstructions and ensure the seed delivery system is functioning properly. Regular cleaning and maintenance after each use can help prevent blockages and keep the seed drill running smoothly.

Inaccurate Depth Placement

Inaccurate seed depth placement can result in uneven crop emergence and reduced yield potential. Check the seed drill’s depth adjustment mechanism, coulters, and furrow openers for proper settings and alignment. Adjust as necessary to achieve the desired seed depth.

Addressing Mechanical Failures

Mechanical failures can occur in any equipment, including seed drills. In the event of a mechanical issue, consult the seed drill’s instruction manual or contact the manufacturer’s customer support for guidance. It may be necessary to replace or repair specific components to resolve the problem.

Safety Considerations

When operating a seed drill, ensuring your safety and the safety of those around you is of paramount importance. By following these safety considerations, you can mitigate potential risks and injuries.

Wearing Proper Protective Gear

Always wear appropriate protective gear when operating a seed drill. This may include safety goggles, ear protection, gloves, and steel-toed boots. Protecting yourself from potential hazards, such as flying debris or noise-related hearing damage, is crucial for a safe working environment.

Avoiding Contact with Moving Parts

Never reach into or come into contact with moving parts of the seed drill while it is in operation. Moving components, such as coulters, furrow openers, or rotating machinery, pose significant risks of injury. Maintain a safe distance from these parts and exercise caution at all times.

Being Cautious of Surroundings

Ensure that the area around the seed drill is clear of obstructions, bystanders, or other equipment. Maintain a safe working distance from power lines, buildings, or other potential hazards. Always be aware of your surroundings and operate the seed drill with caution.

Training and Certification

While operating a seed drill may seem straightforward, seeking expert guidance and training can greatly enhance your proficiency. Attaining certification in seed drill operation ensures that you possess the necessary knowledge and skills to operate the equipment safely and effectively.

Seeking Expert Guidance and Training

Consult experts or agricultural extension services to seek guidance and training in seed drill operation. These resources can provide valuable insights, tips, and techniques specific to your region and crop types. Attending workshops or training programs can further enhance your understanding of seed drill calibration and operation.

Attaining Certification for Proficiency

Some agricultural organizations provide certification programs for seed drill operation. These programs assess your knowledge, skills, and understanding of seed drill calibration and operating procedures. Becoming certified demonstrates your proficiency and commitment to safe and accurate seed drill operation.

Advancements in Seed Drill Technology

Advancements in seed drill technology have revolutionized the planting process, providing farmers with more precise and efficient methods. These advancements include precision planting techniques, digital calibration tools, and automation and GPS integration.

Precision Planting Techniques

Precision planting techniques utilize advanced technology to precisely place seeds in the desired position and depth. These techniques incorporate mechanisms such as hydraulic downforce systems, individual row control, and automatic seed rate adjustments. Precision planting improves seed spacing, depth accuracy, and crop emergence, resulting in increased yields and reduced input costs.

Digital Calibration Tools

Digital calibration tools have simplified the calibration process for seed drills. These tools use sensors and software applications to measure seed flow rates, seed spacing, and other critical parameters. By providing real-time feedback and precise recommendations, digital calibration tools enhance accuracy and reduce calibration time.

Automation and GPS Integration

Automation and GPS integration allow for seamless operation and enhanced precision in seed drill use. Automated systems can control seed metering, depth placement, and spacing adjustments, reducing the need for manual interventions. GPS integration ensures accurate seed placement by providing real-time location information and adjusting seed distribution accordingly.

Conclusion

Proper calibration and operation of a seed drill are essential for accurate and successful planting. By understanding the purpose of a seed drill, familiarizing yourself with its components, and following the outlined steps for calibration and operation, you can ensure optimal crop establishment and maximize your agricultural productivity. Remember to prioritize safety, seek expert guidance and training, and stay updated on advancements in seed drill technology to continually improve your planting results. By using a seed drill effectively, you can cultivate healthy crops and contribute to a sustainable and thriving agricultural industry.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.