This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

Keeping your tillage equipment in pristine condition is crucial for maintaining its efficiency and prolonging its lifespan. In this article, we will walk you through the step-by-step process of properly cleaning and maintaining your tillage equipment. From cleaning the blades to checking the functionality of crucial components, we have got you covered. By following these simple yet effective tips, you will not only ensure your equipment’s optimal performance but also save time and money in the long run. So, let’s get started on your journey to becoming a pro at maintaining your tillage equipment!

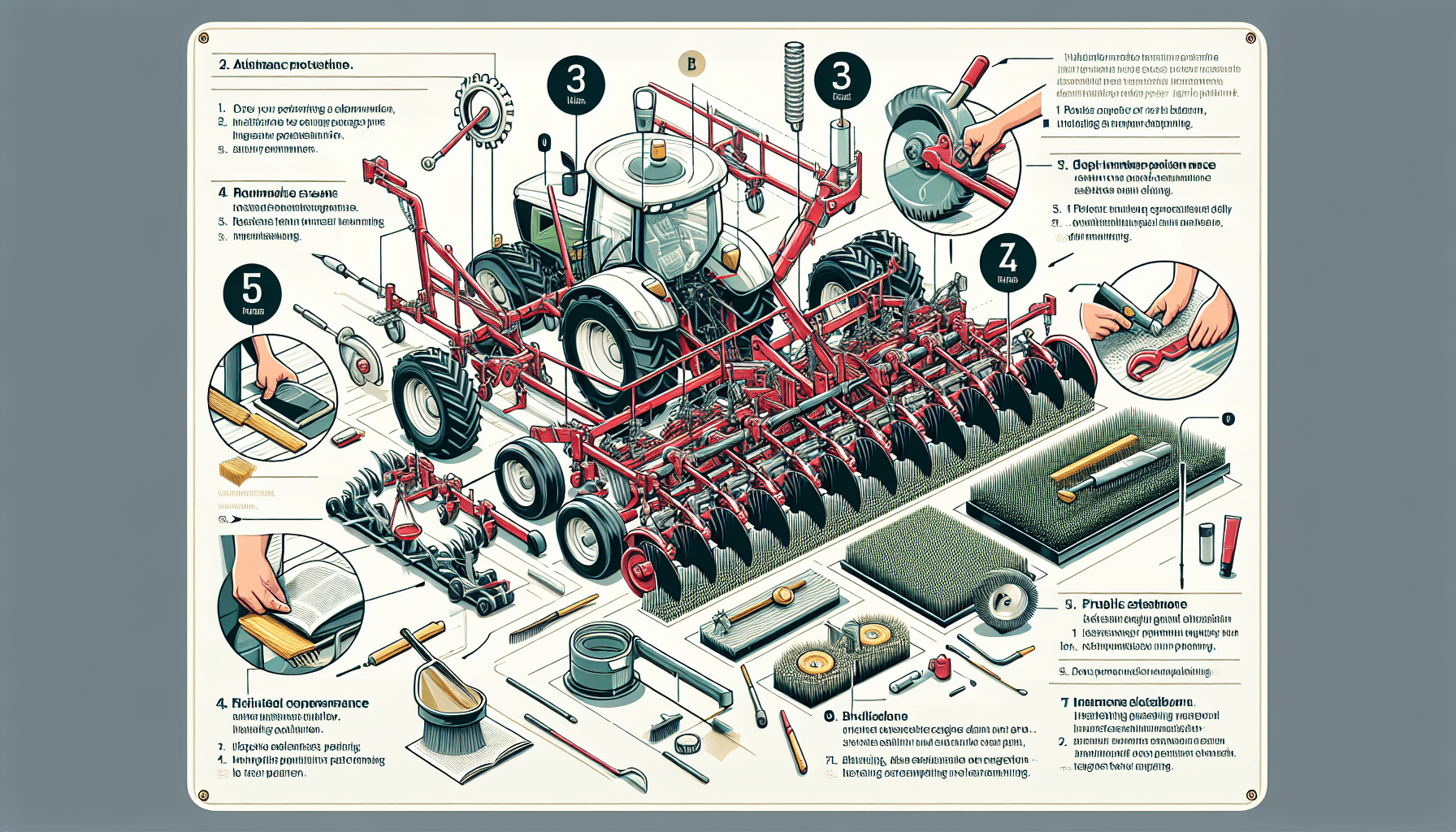

Inspecting Your Tillage Equipment

Checking for damage

The first step in properly maintaining your tillage equipment is to regularly inspect it for any signs of damage. This includes looking for any cracks, dents, or other types of physical damage that may affect the performance of the equipment. Additionally, check for any loose or missing bolts or fasteners that need to be tightened or replaced. By identifying and addressing any damage early on, you can prevent further issues and ensure that your equipment is operating at its best.

Identifying worn parts

In addition to checking for damage, it’s important to identify any worn parts on your tillage equipment. Worn parts can include things like blades, cutting edges, or other components that may have become dull or worn down over time. By identifying these worn parts, you can plan for their replacement or repair, ensuring that your equipment continues to work effectively and efficiently.

Inspecting hydraulic hoses

Another crucial aspect of maintaining your tillage equipment is inspecting the hydraulic hoses. These hoses play a vital role in the operation of your equipment, so it’s important to check for any signs of wear, such as cracks or leaks. Additionally, make sure the hoses are properly connected and secure. Any issues with the hydraulic hoses should be promptly addressed to avoid potential malfunctions or accidents during operation.

Examining bolts and fasteners

The bolts and fasteners on your tillage equipment are responsible for holding everything together. Therefore, it’s essential to examine them regularly for any signs of wear or weakness. Look for rust, corrosion, or any loose fasteners that may need to be tightened or replaced. By ensuring that all bolts and fasteners are in good condition, you can maintain the structural integrity of your equipment and prevent any potential safety hazards.

Cleaning Your Tillage Equipment

Removing dirt and debris

Before starting any maintenance tasks on your tillage equipment, it’s important to remove any dirt and debris that may have accumulated. Use a brush or compressed air to remove loose dirt and debris from the surface of the equipment. This will make it easier to access all areas during the cleaning process and prevent any contaminants from interfering with the maintenance procedures.

Using a pressure washer

Once you have removed the loose dirt and debris, you can further clean your tillage equipment by using a pressure washer. This will help remove stubborn dirt, grime, and other residues that may have built up over time. When using a pressure washer, be sure to follow the manufacturer’s instructions and adjust the pressure accordingly to avoid damaging delicate components.

Cleaning blades and cutting edges

The blades and cutting edges of your tillage equipment play a critical role in its performance, so it’s important to keep them clean and free from any debris or buildup. Use a wire brush or scraper to remove any caked-on dirt or residue from the blades and cutting edges. If necessary, you can also soak them in a degreaser solution to loosen any stubborn grime. Remember to dry the blades thoroughly before reattaching them to the equipment to prevent rusting.

Removing rust and corrosion

If you notice any rust or corrosion on your tillage equipment, it’s important to address it promptly to prevent further damage. Use a wire brush or sandpaper to gently remove the rust or corrosion from affected areas. Once the rust or corrosion is removed, apply a rust inhibitor or protective coating to prevent future corrosion. Regularly inspect your equipment for any signs of rust or corrosion, as prevention is key to maintaining its longevity.

Applying Lubrication

Choosing the right lubricant

Proper lubrication is essential for keeping your tillage equipment running smoothly and efficiently. When choosing a lubricant, consider the specific needs of your equipment and consult the manufacturer’s recommendations. Different types of lubricants may be required for different components, such as grease for pivot points and oil for moving parts. Choose high-quality lubricants that are suitable for the conditions in which your equipment operates.

Applying grease to pivot points

Pivot points on your tillage equipment, such as hinges or joints, require regular greasing to prevent friction and ensure smooth movement. Apply grease to these pivot points using a grease gun or other appropriate lubrication tools. Follow the manufacturer’s recommendations for the appropriate amount of grease to apply and the frequency of greasing.

Lubricating moving parts

In addition to greasing the pivot points, it’s important to lubricate the moving parts of your tillage equipment. This includes bearings, chains, gears, and any other components that require lubrication. Use the recommended type and amount of oil or lubricant specified by the manufacturer. Regularly check the oil levels and top up as needed to maintain proper lubrication.

Maintaining proper oil levels

Checking and maintaining proper oil levels is crucial for the overall performance and longevity of your tillage equipment. Make it a habit to regularly check the oil levels in your equipment’s engine, gearbox, and any other oil-filled components. Ensure that the oil levels are within the manufacturer’s recommended range and top up or replace the oil as necessary. Regular oil changes are also important to remove any contaminants and ensure optimal lubrication.

Replacing or Repairing Parts

Identifying parts that need replacement

During your inspection of the tillage equipment, you may come across parts that are beyond repair and need to be replaced. This could include worn-out blades, damaged hydraulic hoses, or other components that are no longer functioning as intended. It’s important to accurately identify these parts to ensure you order the correct replacements.

Ordering and installing new parts

Once you have identified the parts that need replacement, it’s important to order them promptly to minimize downtime. Contact your equipment manufacturer or reputable suppliers to order the necessary parts. When installing new parts, carefully follow the manufacturer’s instructions and ensure they are properly fitted and secured. Proper installation is essential for maintaining the functionality and safety of your tillage equipment.

Repairing damaged components

In some cases, it may be possible to repair damaged components rather than replacing them entirely. Assess the extent of the damage and consult with experts or professionals to determine if a repair is feasible. If you choose to repair the damaged components, follow the recommended procedures and use appropriate tools and materials. Conduct regular inspections after the repair to ensure the functionality and longevity of the repaired components.

Ensuring proper fit and function

Whether you are replacing or repairing parts, it’s crucial to ensure that they are properly fitted and functioning as intended. Double-check the fit of the new parts and make any necessary adjustments to ensure a proper fit. Test the equipment after the installation or repair to confirm that all components are working correctly. Proper fit and function will contribute to the overall efficiency and performance of your tillage equipment.

Sharpening Blades

Using a sharpening stone or grinder

Sharp blades are essential for effective tillage operations. To sharpen your tillage equipment blades, you can use a sharpening stone or grinder. Follow the manufacturer’s recommendations or consult a professional for guidance on the specific sharpening technique for your blades. Take care to maintain the correct angle and avoid overheating the blades, as this can damage their temper.

Maintaining the correct blade angle

The correct blade angle is crucial for achieving optimal performance and preventing premature wear. Refer to the manufacturer’s guidelines or consult an expert to determine the appropriate blade angle for your specific tillage equipment. Use a sharpening guide or jig to maintain a consistent angle while sharpening the blades. A consistently sharpened blade angle will ensure uniform cutting and minimize strain on the equipment.

Ensuring a clean and sharp cutting edge

When sharpening the blades, it’s important to remove any burrs or nicks and create a clean, sharp cutting edge. Work carefully to remove the minimum amount of material necessary to restore the cutting edge. Ensure that the cutting edge is free from any irregularities or damage that could affect its performance. A clean and sharp cutting edge will result in more precise and efficient tillage operations.

Testing the sharpness of the blades

After sharpening the blades, it’s crucial to test their sharpness before using them on your tillage equipment. Carefully run your fingers along the cutting edge to feel for any rough spots or inconsistencies. Blades should feel uniformly sharp and smooth along their entire length. If you have any doubts about the sharpness, repeat the sharpening process until the blades are properly sharpened. Testing the sharpness will ensure that your tillage equipment performs optimally in the field.

Adjusting Depth and Width Settings

Understanding the correct settings for your tillage equipment

Each tillage equipment model has specific depth and width settings that are recommended for various soil conditions and tasks. Consult the manufacturer’s documentation or an expert to understand the correct settings for your equipment. Familiarize yourself with how these settings affect the performance and outcomes of your tillage operations. Understanding the correct settings will help you achieve the desired results efficiently and effectively.

Adjusting depth settings for different soil conditions

To optimize the effectiveness of your tillage operations, you must adjust the depth settings of the equipment based on the specific soil conditions. For compacted or hard soils, you may need to increase the depth to break up the soil effectively. In softer or looser soils, reducing the depth can prevent excessive soil disturbance. Regularly assess the soil conditions and adjust the depth settings accordingly to achieve the desired tillage results.

Setting the appropriate width for the task at hand

The width setting of your tillage equipment determines the coverage area and the intensity of the tillage. Consider the task at hand and the desired outcomes when adjusting the width setting. For large open fields, a wider width may be suitable to cover a larger area efficiently. However, for more precise or targeted operations, a narrower width may be necessary. Adjust the width setting accordingly to optimize your tillage operations.

Using depth wheels to maintain consistent depth

Some tillage equipment is equipped with depth wheels, which help maintain a consistent working depth. Follow the manufacturer’s instructions on adjusting and positioning the depth wheels to achieve the desired depth. Regularly check the depth wheels for proper alignment and functionality. Proper utilization of depth wheels will help ensure consistency and accuracy in your tillage operations.

Balancing and Leveling

Checking for balance issues

Maintaining proper balance throughout your tillage equipment is crucial for optimal performance and safety. Regularly inspect the equipment for any signs of imbalances, such as uneven weight distribution or misalignment. Check for any visible signs of wear or damage that may contribute to an imbalance. Address any balance issues promptly to prevent further damage and ensure safe operation.

Adjusting weight distribution

Proper weight distribution across your tillage equipment is essential for achieving even tillage depth and minimizing strain on the equipment. If you notice an imbalance, investigate whether it can be resolved by adjusting the weight distribution. Use proper counterweights or other recommended methods to achieve the desired balance. Follow the manufacturer’s guidelines or consult an expert to ensure proper weight distribution.

Leveling the tillage equipment

A level tillage equipment ensures that the work is performed uniformly across the field and helps maintain consistent depth. Use a leveling device or implement to check the levelness of your tillage equipment. Adjust the equipment’s leveling mechanisms, such as wheels or hydraulic adjustments, to achieve a level position. Proper leveling will result in more efficient tillage operations and a more uniform seedbed.

Ensuring proper seedbed preparation

Balancing and leveling your tillage equipment contributes to the successful preparation of a proper seedbed. A well-prepared seedbed is essential for seed-to-soil contact and optimal seed germination. By maintaining proper balance and levelness, you can help ensure that the soil is evenly worked, allowing for uniform distribution of seeds and nutrients. A properly prepared seedbed sets the foundation for healthy plant growth and higher yields.

Proper Storage

Cleaning before storage

Before storing your tillage equipment, it’s important to thoroughly clean it to remove any dirt, debris, or residual moisture. Use a brush, compressed air, or a pressure washer to remove any remaining dirt or residue. Pay extra attention to areas that are prone to rust or corrosion. Ensure that all exposed metal surfaces are dry to prevent rust formation during storage.

Protecting against rust and moisture

To protect your tillage equipment from rust and moisture during storage, apply a rust inhibitor or protective coating to the metal surfaces. This will create a barrier against environmental elements that can cause rust or corrosion. Additionally, consider using desiccant packs or other moisture-absorbing products inside storage compartments to reduce the risk of moisture accumulation.

Storing in a dry and secure location

Finding a suitable storage location for your tillage equipment is essential for its longevity and protection. Choose a dry, well-ventilated area that is free from excessive moisture and temperature fluctuations. Ideally, store the equipment indoors to minimize exposure to the elements. If indoor storage is not possible, consider using a sturdy and weatherproof cover or tarp to protect the equipment from rain, snow, and other environmental factors.

Covering or tarping the equipment

When storing your tillage equipment, consider covering or tarping it to provide an additional layer of protection. This will shield the equipment from dust, debris, and UV radiation, which can cause fading or deterioration of certain components. Ensure that the cover or tarp is securely fastened and provides adequate coverage for all exposed areas of the equipment. Regularly inspect the cover or tarp for any signs of wear or damage and replace it if needed.

Regular Maintenance Schedule

Creating a maintenance checklist

To ensure that all necessary maintenance tasks are performed on time, create a comprehensive maintenance checklist for your tillage equipment. Include regular inspections, cleaning tasks, lubrication, blade sharpening, and other recommended maintenance procedures. Having a well-organized checklist will help you stay on top of your maintenance routine.

Scheduling routine inspections and cleaning

Regular inspections and cleaning should be scheduled at suitable intervals to maintain the performance and longevity of your tillage equipment. Depending on the frequency of use and the operating conditions, establish a routine for inspecting and cleaning your equipment. This can be daily, weekly, monthly, or as recommended by the manufacturer. Consistently following a maintenance schedule will help prevent issues and catch potential problems early on.

Documenting maintenance tasks

Keeping records of your maintenance tasks is essential for tracking the history of your tillage equipment and ensuring accountability. Document the date, tasks performed, observations, and any notes or recommendations. Include any parts replaced, repairs made, or changes in settings. This documentation will assist in troubleshooting, warranty claims, and future maintenance planning.

Following manufacturer’s recommendations

Finally, it’s crucial to follow the manufacturer’s recommendations for maintaining your tillage equipment. The manufacturer’s guidelines are based on extensive research and testing, ensuring the optimal operation and longevity of your equipment. Familiarize yourself with the manufacturer’s documentation, including the owner’s manual and maintenance guidelines. Adhering to these recommendations will help you maximize the performance and lifespan of your tillage equipment.

Safety Precautions

Wearing appropriate personal protective equipment

When working with tillage equipment, always prioritize your safety by wearing the appropriate personal protective equipment (PPE). This may include safety glasses, gloves, hearing protection, and steel-toed boots. PPE is essential for protecting yourself from potential hazards such as flying debris, loud noises, and sharp edges. Always follow the recommended PPE guidelines and ensure that it is in good condition before use.

Following proper lockout/tagout procedures

Before conducting any maintenance or repair tasks on your tillage equipment, it’s important to follow proper lockout/tagout procedures. This involves disconnecting the equipment from its power source, locking or tagging out the energy isolation devices, and ensuring that the equipment is inoperable. Lockout/tagout procedures are critical for preventing accidental startup or release of stored energy, protecting yourself and others from harm.

Working in well-lit and well-ventilated areas

To ensure a safe working environment, always work in well-lit and well-ventilated areas when performing maintenance tasks on your tillage equipment. Sufficient lighting will help you identify potential hazards or irregularities more easily, reducing the risk of accidents. Adequate ventilation will ensure that harmful fumes or gases are properly expelled, maintaining air quality and preserving your health.

Avoiding contact with moving parts

One of the most important safety precautions when working with tillage equipment is to avoid any contact with moving parts. Never reach into or attempt to work on equipment while it is in operation. The rotating blades, gears, or other moving components can cause serious injuries. Always ensure that the equipment is properly shut off and that it has come to a complete stop before approaching or working on it.

By following these comprehensive guidelines and implementing regular maintenance routines, you can ensure the optimal performance, longevity, and safety of your tillage equipment. Properly inspecting, cleaning, lubricating, and maintaining your equipment will not only improve its efficiency but also maximize your agricultural productivity. Remember to prioritize safety and always follow the manufacturer’s recommendations to get the most out of your tillage equipment.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.