This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

Hello there! If you’re in the market for a fertilizer injector to enhance the efficiency of your irrigation system, it’s important to consider several key factors before making a decision. Factors such as the type of fertilizer you plan to use, the size of your irrigation system, and the level of precision required can all play a role in determining the best injector for your needs. By taking the time to carefully evaluate these factors, you can ensure that you select a fertilizer injector that will help you achieve optimal results in your irrigation practices. Have you been considering investing in a fertilizer injector for your irrigation system, but are unsure of where to start? Selecting the right fertilizer injector is crucial to ensuring that your plants receive the nutrients they need to thrive. In this article, we will walk you through the key factors to consider when choosing a fertilizer injector for your irrigation system. By the end of this article, you will have the knowledge needed to make an informed decision that will benefit your crops and your wallet. Let’s dive in!

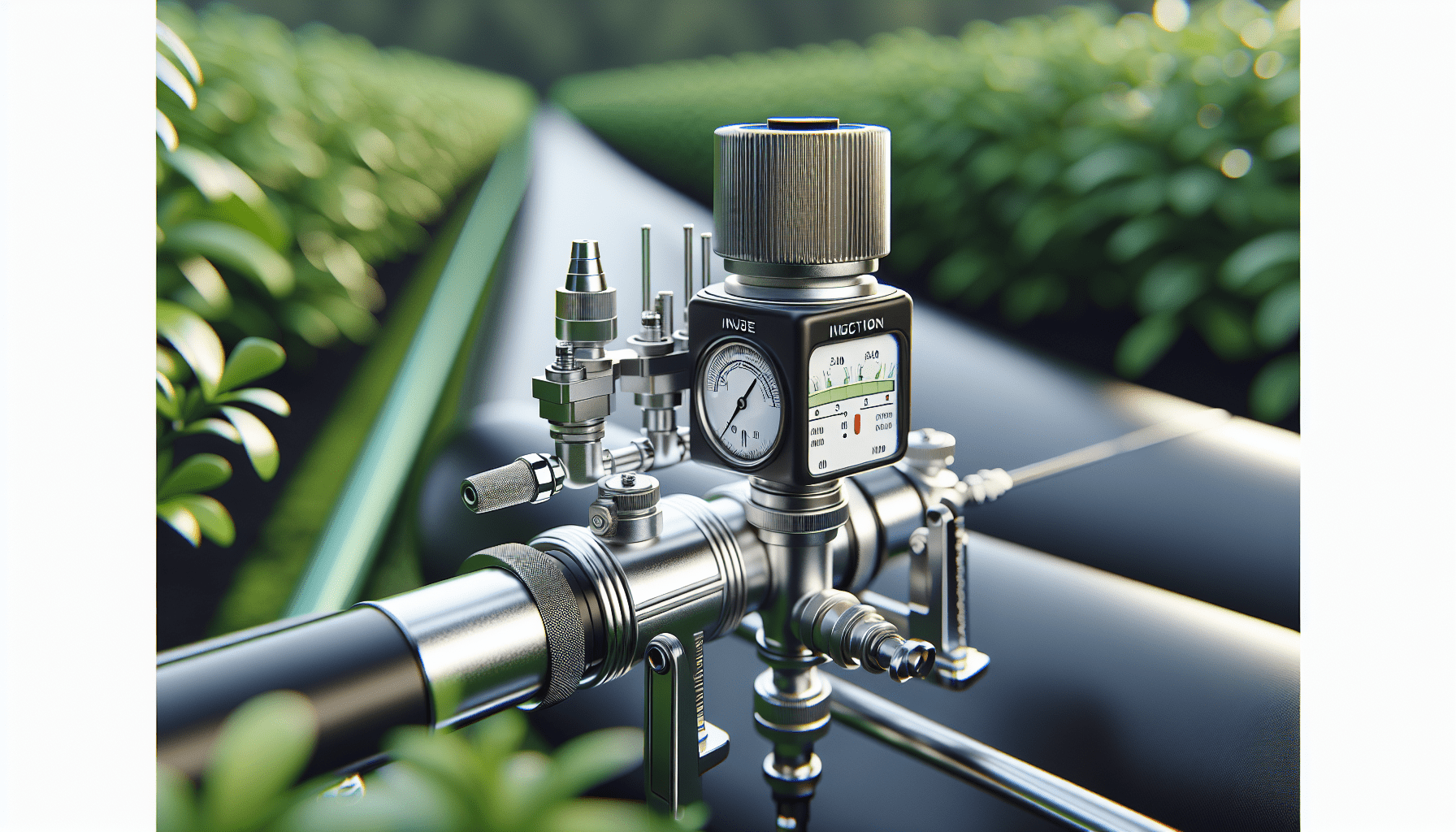

Understanding Fertilizer Injectors

Fertilizer injectors are devices that are used to deliver fertilizers, pesticides, and other water-soluble nutrients directly to plants through irrigation systems. These devices work by mixing the fertilizer solution with water and distributing it evenly to the entire crop. By automating this process, fertilizer injectors help ensure that plants receive a consistent and accurate amount of nutrients, leading to healthier and more productive crops.

The Importance of Using a Fertilizer Injector

Using a fertilizer injector in your irrigation system offers several advantages. Firstly, it allows for precise control over the amount of fertilizer being delivered to your plants. This is crucial as over or under-application of fertilizers can lead to nutrient deficiencies or toxicities, which can harm your plants. Secondly, fertilizer injectors help save time and labor by automating the fertilization process, freeing up time for other tasks on the farm. Lastly, by delivering fertilizers directly to the root zone of plants, fertilizer injectors maximize nutrient uptake and reduce waste, making your fertilizers more cost-effective.

Types of Fertilizer Injectors

There are several types of fertilizer injectors available on the market, each with its own advantages and disadvantages. It is essential to understand the differences between these types to choose the one that best suits your needs.

Venturi Fertilizer Injectors

Venturi fertilizer injectors are one of the most popular types of injectors and are known for their simplicity and reliability. These injectors operate based on the principle of fluid dynamics, where the flow of water creates a vacuum that draws the fertilizer solution into the irrigation line. Venturi injectors are suitable for small to medium-sized operations and are cost-effective options for delivering fertilizers.

Diaphragm Fertilizer Injectors

Diaphragm fertilizer injectors use a mechanical diaphragm to regulate the flow of fertilizer solution into the irrigation line. These injectors are known for their accuracy and consistency in delivering nutrients to plants. Diaphragm injectors are ideal for medium to large-scale operations where precise control over nutrient delivery is essential.

Electric Fertilizer Injectors

Electric fertilizer injectors are powered by an electric motor that regulates the flow of the fertilizer solution based on preset settings. These injectors offer the most precise control over the amount of fertilizer being delivered and are suitable for large-scale operations with complex nutrient management needs. Electric injectors are the most expensive option but offer unparalleled accuracy and automation.

Factors to Consider When Selecting a Fertilizer Injector

When choosing a fertilizer injector for your irrigation system, several factors need to be taken into account to ensure that you select the right one for your specific needs. Let’s explore these key factors in more detail.

Flow Rate

The flow rate of a fertilizer injector refers to the amount of water passing through the injector in a given period. It is essential to match the flow rate of the injector to the flow rate of your irrigation system to ensure that the fertilizer solution is evenly distributed to your plants.

Injection Ratio

The injection ratio of a fertilizer injector indicates the proportion of fertilizer being mixed with water. Different crops have varying nutrient requirements, so it is crucial to select an injector with an adjustable injection ratio to meet the needs of your specific crops.

Compatibility

Not all fertilizer injectors are compatible with every type of fertilizer. Some injectors may be designed for liquid fertilizers, while others are suitable for water-soluble powders. Make sure to choose an injector that is compatible with the type of fertilizer you plan to use to avoid clogging or damage to the injector.

Maintenance and Cleaning

Regular maintenance and cleaning are essential to ensure the proper functioning of your fertilizer injector. Look for injectors that are easy to disassemble and clean to prevent clogging and ensure consistent nutrient delivery. Consider how often you are willing to clean and maintain the injector when making your selection.

Cost

The cost of a fertilizer injector can vary significantly depending on the type, size, and features it offers. Consider your budget and the long-term benefits of investing in a high-quality injector that meets your needs. While cost is an important factor, prioritize the performance and reliability of the injector to maximize the benefits to your crops.

Selecting the Right Size Fertilizer Injector

Choosing the right size fertilizer injector is crucial to ensuring that your plants receive the correct amount of nutrients. The size of the injector is determined by its capacity to deliver a specific volume of fertilizer solution.

Matching Injector Size to Irrigation System

Select an injector that matches the size of your irrigation system to ensure that the fertilizer solution is evenly distributed throughout your crop. An injector that is too small may not deliver enough nutrients, while an injector that is too large may lead to over-application of fertilizers.

Consider the Pump Capacity

The pump capacity of your irrigation system plays a significant role in determining the size of the fertilizer injector needed. Calculate the pump capacity based on the flow rate and pressure requirements of your irrigation system to select an injector that can keep up with the demands of your crop.

Future Expansion

Consider the potential for future expansion of your operation when choosing the size of the fertilizer injector. Select an injector that can accommodate increased flow rates and nutrient requirements as your farm grows to avoid the need for frequent upgrades.

Installing and Maintaining Your Fertilizer Injector

Proper installation and maintenance of your fertilizer injector are essential to ensure its efficient operation and longevity. Follow these steps to install and maintain your injector correctly.

Installation

- Install the injector downstream from the filter and before any pressure regulators or control valves in your irrigation system.

- Ensure that the injector is mounted securely to prevent movement during operation.

- Connect the injector to the water supply line and adjust the injection ratio to match the needs of your crops.

- Test the injector for leaks and proper operation before running it with your irrigation system.

Maintenance

- Clean the injector regularly to prevent clogging and ensure consistent nutrient delivery.

- Check for worn or damaged parts and replace them as needed to maintain the performance of the injector.

- Keep the injector lubricated and free from debris to prevent malfunctions and prolong its lifespan.

- Monitor the injector for any signs of leaks, corrosion, or damage and address any issues promptly to prevent downtime.

Troubleshooting Common Issues with Fertilizer Injectors

Despite proper installation and maintenance, fertilizer injectors may encounter issues that affect their performance. Here are some common problems and solutions to help troubleshoot these issues.

Clogging

Clogging is a common issue with fertilizer injectors that can result from debris or mineral buildup in the injector. To prevent clogging, clean the injector regularly and use high-quality fertilizers that dissolve easily in water.

Inconsistent Nutrient Delivery

If your plants are showing signs of nutrient deficiencies or toxicities, the injector may be delivering an inconsistent amount of fertilizer. Check the flow rate and injection ratio of the injector and adjust them as needed to ensure a consistent nutrient supply.

Leaks

Leaks in the injector can lead to wasted fertilizers and uneven distribution of nutrients. Inspect the injector for leaks and tighten any loose connections. Replace damaged seals or gaskets to prevent leaks and ensure proper operation.

Reduced Pressure

A drop in pressure in the irrigation system can affect the performance of the injector. Check for obstructions in the water supply line, such as kinks or blockages, and address them to restore proper pressure to the injector.

Conclusion

Selecting the right fertilizer injector for your irrigation system is a crucial decision that can significantly impact the health and productivity of your crops. By considering the key factors outlined in this article, such as flow rate, injection ratio, compatibility, maintenance, and cost, you can make an informed choice that meets the needs of your specific operation. Remember to match the size of the injector to your irrigation system, install and maintain it correctly, and troubleshoot common issues to ensure optimal performance. With the proper fertilizer injector in place, you can provide your plants with the nutrients they need to thrive and achieve the best possible yields. Happy farming!

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.