This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

Ever wondered about the various types of harvesters and how they’re put to use? This article will provide you with a comprehensive overview of the different types of harvesters and their applications. Whether you’re curious about agricultural harvesters, logging harvesters, or even planetary exploratory harvesters, we’ve got you covered. So, sit back, relax, and let’s embark on a journey through the fascinating world of harvesters!

Types of Harvesters

Harvesters are vital pieces of equipment in the agriculture industry. They are designed to efficiently and effectively gather crops from the fields, reducing the manual labor required for harvesting. There are various types of harvesters available, each specifically designed to suit the needs of different crops. In this article, we will explore the different types of harvesters, their functions, components, harvesting processes, usage, benefits, maintenance, and safety tips.

This image is property of www.tractorjunction.com.

Combine Harvester

Definition and Function

The combine harvester, also known as the combine, is a versatile machine that performs several agricultural tasks simultaneously. Its main function is to harvest, thresh, and clean grains in a single operation. This efficiency makes it an essential tool for modern grain farming.

Components and Features

A combine harvester consists of several key components. The cutting platform, with its sharp blades or rotating reel, cuts the crop close to the ground and feeds it into the machine. The threshing drum or rotor separates the grain from the straw. The cleaning, separation, and collection systems remove impurities and transfer the grain to the tank or hopper.

Modern combines come equipped with advanced features such as GPS navigation systems, yield monitors, and automatic adjustments. These features improve efficiency, accuracy, and overall performance during harvesting.

Harvesting Process

The harvesting process with a combine harvester begins by adjusting the cutting height to ensure the crop is cut as close to the ground as possible while avoiding any soil contamination. The crop is then fed into the machine through the cutting platform. As the crop passes through the threshing drum, the grain is separated from the straw. The grain is collected in the tank, while the straw is deposited back onto the field.

Usage and Benefits

Combine harvesters are primarily used for harvesting grains such as wheat, barley, oats, and corn. The advantage of using a combine harvester is the significant time and labor savings it offers compared to traditional harvesting methods. The machine’s ability to simultaneously cut, thresh, and clean the crop streamlines the harvesting process, increasing efficiency and productivity.

Maintenance and Safety Tips

To ensure smooth operation and longevity of your combine harvester, regular maintenance is crucial. This includes cleaning the machine after each use, checking and replacing worn-out parts, and servicing the engine and other components as recommended by the manufacturer. Additionally, practicing safety precautions such as wearing appropriate protective gear, conducting pre-operational checks, and following operational guidelines will help prevent accidents and ensure operator safety.

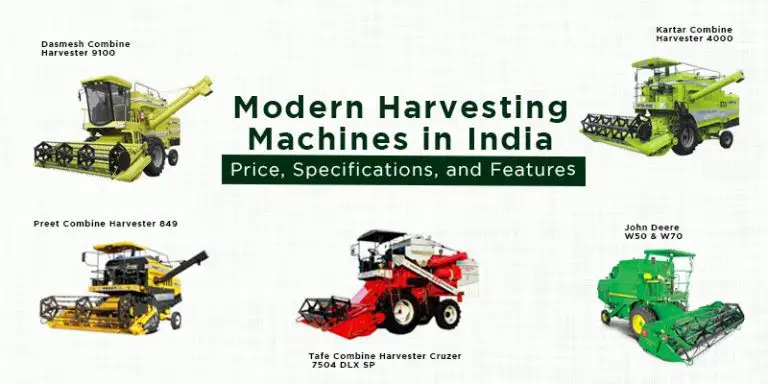

This image is property of www.combineharvestermachine.com.

Forage Harvester

Definition and Function

A forage harvester, also known as a silage harvester or chopper, is designed to harvest and chop forage crops, such as corn, grass, alfalfa, and sorghum, into small pieces for livestock feed or silage production.

Components and Features

The primary components of a forage harvester include a cutting head, which cuts the crop, and a chopping mechanism, usually equipped with rotating blades or rollers, which chops the crop into smaller pieces. It also features a collection system, which transfers the chopped forage into a trailer or wagon for transport.

Modern forage harvesters are equipped with features such as automatic length control, moisture sensors, kernel processing units, and yield mapping systems. These advanced features enhance precision, efficiency, and forage quality.

Harvesting Process

The harvesting process with a forage harvester begins by adjusting the cutting height to achieve the desired length of the chopped forage. The crop is then fed into the machine, where it passes through the cutting head and is chopped into small pieces by the chopping mechanism. The chopped forage is collected and transported to a storage facility or livestock feeding area.

Usage and Benefits

Forage harvesters are primarily used in livestock farming as a means of producing high-quality feed. By harvesting crops into small pieces, the forage harvester improves digestibility and nutrient availability for animals. Additionally, using a forage harvester allows farmers to preserve excess crops as silage, ensuring a reliable and nutritious food source for their livestock during the winter months.

Maintenance and Safety Tips

Regular maintenance is essential to keep your forage harvester in optimal condition. This includes cleaning the machine after each use, greasing moving parts, checking and replacing worn-out components, and maintaining cutting knives or blades. Safety precautions, such as ensuring all guards are in place, keeping bystanders at a safe distance, and wearing appropriate protective gear when operating the machine, should always be followed to prevent accidents.

This image is property of khetigaadi.com.

Cotton Harvester

Definition and Function

A cotton harvester, also known as a cotton picker, is a specialized machine designed to harvest cotton fibers from cotton plants. This highly efficient harvester automates the typically labor-intensive process of picking cotton by hand.

Components and Features

The key components of a cotton harvester include a picking system, a cleaning system, and a collection system. The picking system consists of spindles or doffers with attached spiky pads that grab and pull the cotton fibers from the plant. The cleaning system removes unwanted materials such as leaves, stems, and dirt, while the collection system transfers the harvested cotton to a basket or container.

Modern cotton harvesters are equipped with advanced features such as onboard module builders, which compress and package the harvested cotton into modules for easy handling and transportation.

Harvesting Process

The harvesting process with a cotton harvester begins by setting the machine’s speed, spacing, and other settings to suit the crop and field conditions. As the machine moves through the field, the picking units grab the cotton fibers from the plants. The harvested cotton is then cleaned and transferred to the collection system, which stores the cotton until it can be unloaded.

Usage and Benefits

Cotton harvesters are primarily used in cotton-producing regions worldwide. They provide significant advantages over manual labor by dramatically increasing harvesting efficiency and reducing dependence on human workers. Cotton harvested by machines is usually cleaner and of higher quality, resulting in improved fiber length, strength, and overall value.

Maintenance and Safety Tips

Proper maintenance of your cotton harvester is essential for optimal performance and longevity. Regularly inspecting and cleaning the machine, checking and replacing worn-out parts, and conducting scheduled servicing according to the manufacturer’s recommendations will help ensure smooth operation. Additionally, adhering to safety protocols, such as wearing protective clothing, practicing safe operating procedures, and conducting regular safety checks, will minimize the risk of accidents and injuries.

This image is property of khetigaadi.com.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.