This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

Are you curious about the world of sprayers and how they are utilized in various industries? Look no further, as this article explores the different types of sprayers available and delves into their functions and applications. Whether you are a homeowner looking for a sprayer for your garden or a professional in need of a specialized sprayer for your industry, we’ve got you covered. Discover the fascinating world of sprayers and their diverse uses in this informative article.

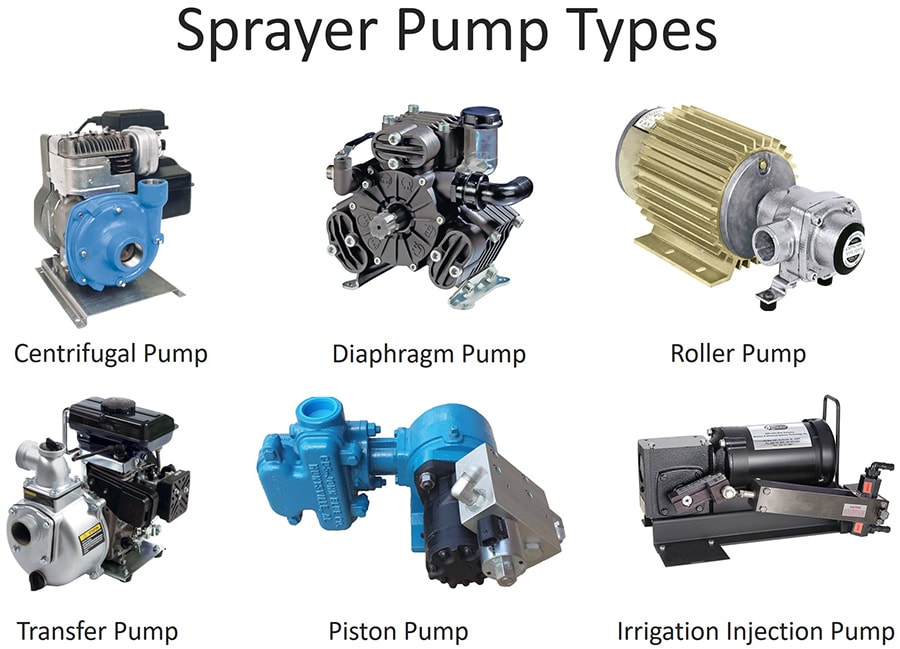

This image is property of www.sprayersupplies.com.

Airless Sprayers

Operating Principle

Airless sprayers, as the name suggests, do not rely on air to atomize the coating material. Instead, they use a high-pressure pump to force the paint or other liquid through a small orifice in the spray gun. The high-pressure stream breaks up the liquid into tiny droplets, resulting in a fine mist that provides even coverage on surfaces.

Applications

Airless sprayers are commonly used in large-scale painting projects, such as painting exterior walls, fences, and industrial equipment. They are also effective for applying thick coatings, such as latex paint, epoxy, and varnish.

Advantages

One of the major advantages of airless sprayers is their speed. They can cover large areas quickly, making them ideal for painting large surfaces. Additionally, airless sprayers can handle a wide range of coating materials, from thin stains to thick latex paints, making them versatile tools for various applications. They also provide a smooth and even finish, reducing the need for touch-ups.

Disadvantages

While airless sprayers offer numerous benefits, they do have some drawbacks. The high-pressure nature of these sprayers can lead to overspray, which may result in wasted paint and potential environmental concerns. Furthermore, the high pressure requires careful control to avoid excessive coating build-up on the surface, as it can cause drips or uneven coverage. Additionally, airless sprayers tend to be more expensive compared to other types of sprayers.

High-Volume, Low-Pressure (HVLP) Sprayers

Operating Principle

HVLP sprayers, as the name implies, utilize a high-volume of air at a low pressure to atomize the coating material. The air is generated by a turbine or compressor and is released through a nozzle, where it mixes with the coating material, resulting in a high volume of fine particles being produced.

Applications

HVLP sprayers are commonly used for finishing and detail work, such as painting furniture, cabinets, and trim. They are also suitable for automotive painting, as they provide a smooth and flawless finish.

Advantages

HVLP sprayers have some distinct advantages. They produce minimal overspray, which reduces waste and ensures a higher transfer efficiency, resulting in less material being wasted. HVLP sprayers also provide a high-quality finish with less risk of paint runs or drips. Additionally, they are relatively easy to clean and maintain.

Disadvantages

One of the disadvantages of HVLP sprayers is their slower application speed compared to airless sprayers. This can make them less efficient for large-scale projects that require quick application. Additionally, HVLP sprayers may struggle with thicker coatings, as the low pressure may not generate enough force to atomize them effectively. They also tend to be more expensive than conventional spray guns.

Handheld Sprayers

Operating Principle

Handheld sprayers are portable and typically powered by electricity or rechargeable batteries. They utilize air or a pump mechanism to atomize the coating material, which is then sprayed onto the surface through a nozzle.

Applications

Handheld sprayers are versatile tools suitable for a variety of applications. They are commonly used for small-scale projects, such as painting furniture, crafts, and touch-ups. They are also convenient for spraying pesticides in gardens and other outdoor areas.

Advantages

The portability of handheld sprayers is their primary advantage. They offer ease of use and maneuverability, allowing you to reach tight spaces and intricate details with ease. Additionally, handheld sprayers are generally more affordable compared to larger sprayers. They are also relatively easy to clean and maintain.

Disadvantages

One of the main disadvantages of handheld sprayers is their limited capacity. Due to their smaller size, they may require frequent refills, which can be time-consuming for larger projects. Handheld sprayers also tend to produce more overspray, leading to potential wastage and increased clean-up efforts. Furthermore, their limited power may result in slower application speeds compared to other sprayers.

Backpack Sprayers

Operating Principle

Backpack sprayers, as the name suggests, are worn like a backpack and are powered by a pump mechanism. They typically rely on air pressure or manual pumping to spray the coating material onto the surface.

Applications

Backpack sprayers are commonly used for outdoor applications, such as applying pesticides, herbicides, and fertilizers in gardens, agricultural fields, and landscape maintenance. They are also suitable for small-scale painting projects, such as fence painting or touch-ups.

Advantages

Backpack sprayers offer excellent portability and mobility. The backpack design allows for hands-free operation, providing ease and convenience while navigating through various terrains. They also provide a consistent and controlled spray pattern, ensuring even coverage. Additionally, backpack sprayers often have larger capacities compared to handheld sprayers, reducing the need for frequent refills.

Disadvantages

One of the disadvantages of backpack sprayers is their weight and fatigue associated with extended use. Carrying a filled backpack can be tiring, especially for more significant projects. Additionally, backpack sprayers may require regular pumping or recharging, which can slow down the application process. They may also have limitations in terms of the type or viscosity of the coating material they can handle.

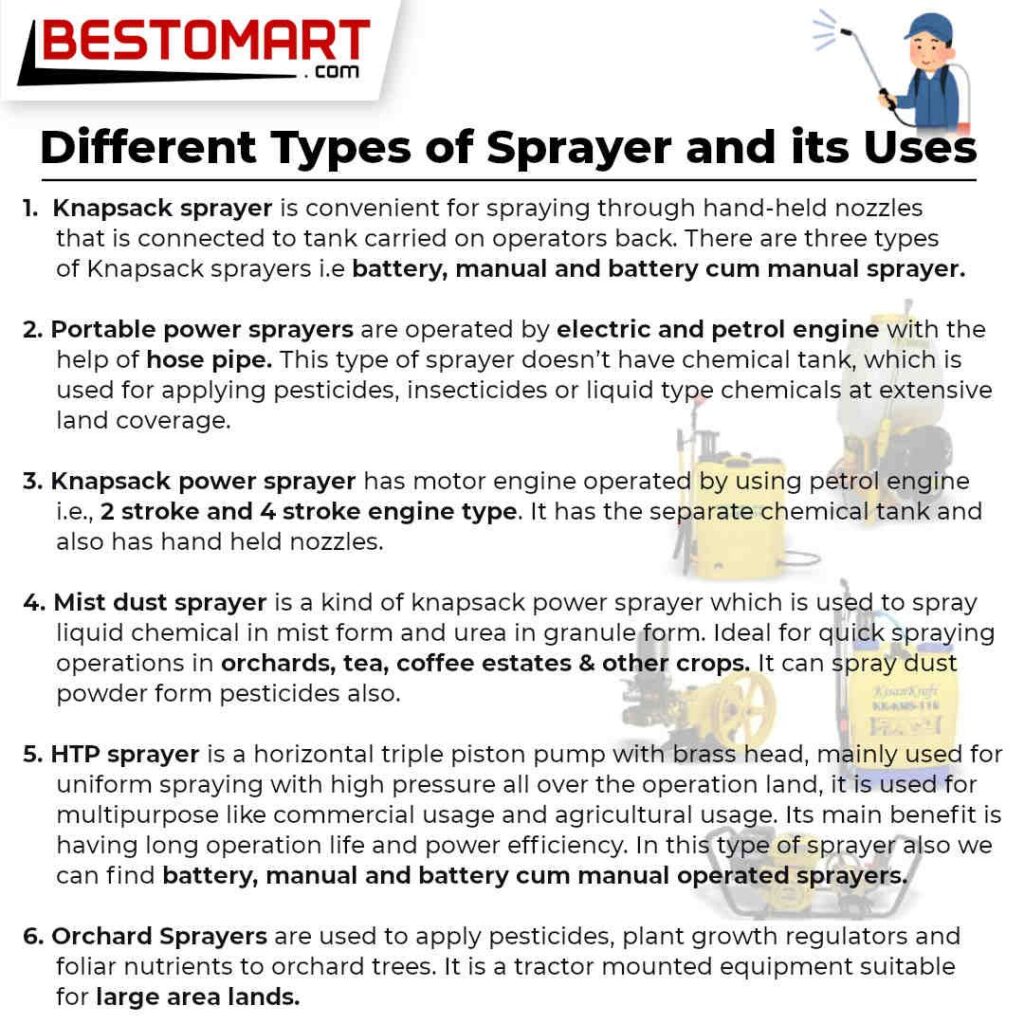

This image is property of www.kisankraft.com.

Compression Sprayers

Operating Principle

Compression sprayers utilize a hand-operated pump to build pressure within a tank, allowing the coating material to be sprayed onto the surface through a nozzle. They rely on the conversion of mechanical energy into pressure to atomize the liquid.

Applications

Compression sprayers are commonly used for applying various liquids, such as herbicides, insecticides, and fertilizers in gardening and agricultural settings. They are also suitable for small-scale painting projects, such as staining decks or applying sealants.

Advantages

The main advantage of compression sprayers is their simplicity and ease of use. They are typically less complex than other types of sprayers, making them straightforward to operate and maintain. Compression sprayers are also relatively affordable compared to more advanced sprayer models.

Disadvantages

One of the limitations of compression sprayers is their lower pressure compared to other sprayers. This can result in a narrower spray pattern and lower atomization, potentially affecting the quality of the finish. Compression sprayers may also have a smaller capacity and require frequent refills for larger projects. Additionally, they may require more effort and time for pumping, which can be tiring for extended use.

Low-Pressure Sprayers

Operating Principle

Low-pressure sprayers rely on a low-pressure air supply to atomize the coating material. They use compressed air to propel the liquid onto the surface through a nozzle, resulting in a controlled, fine mist.

Applications

Low-pressure sprayers are commonly used for smaller painting or finishing projects, such as painting furniture, crafts, and touch-ups. They are also suitable for automotive detailing, as they provide precise application and minimize overspray.

Advantages

Low-pressure sprayers offer several advantages. They provide a high-quality finish with minimal overspray, ensuring efficient use of the coating material. The controlled, low-pressure application reduces the risk of drips or runs, resulting in a smooth and flawless finish. Additionally, low-pressure sprayers are relatively easy to clean and maintain.

Disadvantages

One of the disadvantages of low-pressure sprayers is their slower application speed compared to higher pressure sprayers like airless or HVLP. This can make them less efficient for large-scale projects that require quick application. Additionally, low-pressure sprayers may struggle with thicker coatings, as the lower pressure may not provide enough force for effective atomization. They may also have limitations in terms of the distance they can spray.

This image is property of www.sprayersupplies.com.

Boom Sprayers

Operating Principle

Boom sprayers are commonly used in agriculture and landscaping. They consist of a long boom arm equipped with multiple spray nozzles, which are connected to the pump and liquid supply. The boom arm can be mounted on tractors or vehicles and is typically hydraulically controlled.

Applications

Boom sprayers are primarily used for large-scale agricultural applications, such as spraying fertilizers, herbicides, and pesticides on crops. They are also utilized for maintaining large lawns, golf courses, and public parks.

Advantages

The main advantage of boom sprayers is their ability to cover large areas efficiently. The wide coverage provided by the multiple nozzles and the boom arm saves time and labor. Boom sprayers also provide precise application and can be easily adjusted for different crop or terrain requirements.

Disadvantages

One of the disadvantages of boom sprayers is their cost and complexity. The equipment required for boom sprayers, including the boom arm, pump, and control systems, can be expensive. Additionally, the size and weight of the boom arm can limit access to certain areas, such as narrow rows or uneven terrains. Precise calibration and maintenance are crucial for optimal performance.

Cylinder Sprayers

Operating Principle

Cylinder sprayers, also known as foamers, utilize compressed air to produce foam for various applications. The liquid is mixed with air, causing it to expand and create foam, which is then sprayed onto the targeted surface.

Applications

Cylinder sprayers find applications in various industries, such as agriculture, sanitation, and cleaning. They are commonly used for applying disinfectants, sanitizers, and cleaning solutions in large-scale settings, such as livestock facilities, food processing plants, and public spaces.

Advantages

The main advantage of cylinder sprayers is their ability to generate foam, which provides better adhesion and coverage on vertical and irregular surfaces. Foam also has increased contact time, allowing for better penetration and effectiveness of the applied solution. Additionally, cylinder sprayers offer versatility, as they can produce different foam densities depending on the application requirements.

Disadvantages

One of the limitations of cylinder sprayers is their specific application. They are primarily designed for foam-based solutions and may not be suitable for other coating materials. Cylinder sprayers may also require adequate training and proper cleaning to avoid cross-contamination between different solutions. Furthermore, they may have higher initial costs compared to traditional sprayers, as they require specialized equipment for foam generation.

This image is property of i.ytimg.com.

Ultrasonic Sprayers

Operating Principle

Ultrasonic sprayers utilize high-frequency sound waves to transform liquids into a fine mist. The liquid is vibrated at ultrasonic frequencies, creating small droplets that are uniformly sprayed onto the target surface.

Applications

Ultrasonic sprayers have a wide range of applications, including pharmaceuticals, food and beverage, agriculture, and electronics. They are particularly useful for coating delicate objects, such as electronic components, as the fine mist ensures even coverage without causing damage.

Advantages

The main advantage of ultrasonic sprayers is their ability to produce a highly uniform and precise spray pattern. The fine droplets generated by the ultrasonic waves result in minimal overspray and excellent surface coverage. Ultrasonic sprayers are also ideal for coating objects with complex shapes or intricate details due to their precise application. Additionally, they are often used for applications that require minimal heat generation or low chemical exposure.

Disadvantages

One of the disadvantages of ultrasonic sprayers is their higher cost compared to traditional sprayers. The sophisticated technology involved in ultrasonic systems contributes to their higher price. Ultrasonic sprayers also require proper calibration and maintenance to ensure optimal performance, which may require training or technical expertise. Furthermore, they may have limitations in terms of the viscosity and flow characteristics of the coating material they can handle.

Hand Pump Sprayers

Operating Principle

Hand pump sprayers, also known as pressure sprayers, rely on manual pumping to pressurize the liquid within a tank. The pressure generated forces the liquid through a nozzle, resulting in a controlled spray onto the target surface.

Applications

Hand pump sprayers are versatile tools used for various applications in gardening, agriculture, and household tasks. They are commonly employed for applying fertilizers, pesticides, herbicides, and cleaning solutions in both outdoor and indoor settings.

Advantages

The main advantage of hand pump sprayers is their simplicity and ease of use. They do not require external power sources or complicated mechanisms, making them accessible to users of all skill levels. Hand pump sprayers are also relatively affordable compared to other sprayers, making them a cost-effective choice for small-scale projects. Additionally, they offer portability and maneuverability, allowing for flexibility in application.

Disadvantages

One of the limitations of hand pump sprayers is the physical effort required for manual pumping. This can be tiring for extended use or larger projects. Hand pump sprayers also tend to have smaller capacities compared to other sprayers, leading to more frequent refills. Additionally, the pressure generated by hand pump sprayers may be lower compared to other types of sprayers, potentially affecting the quality and coverage of the spray.

This image is property of pbs.twimg.com.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.